|

|

10-16-2008, 10:56 PM

10-16-2008, 10:56 PM

|

#21

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Quote:

|

Originally Posted by frank

I have seen guys pull automotive trailing arms back into alignment as well. It is certainly doable. The only 'catch' could be that machine time exceeds the axle cost, but it never hurts to ask!

I wouldn't be shocked to find that the ~1* of camber John shows in the picture is in the ballpark. Like I mentioned before, I don't have a ton of trailer experience, but that much camber is common on an auto trailing axle for stability and tracking. Same for a tad bit of toe-in. I think the last one I did was .5* camber. But it is entirely possible a trailer axle is setup dead square. I would think (hope) that Alko could provide the alignment specs.

I think your measurement techniques should be solid, John. I did similar things when I built my last axle, and once it was finished, we got it on the car and onto the alignment rack. We found it to be dead on one side, the other side < .1* out. The guy running the rack said that's better than most stockers and he couldn't believe we built it on the floor

- Frank |

Frank

Once I find where this thing is bent, I think an alignment bending to correct verses new alxes is soon to come.

Still hunting for the spec's. The heavy toe in on the left rear sticks out like a sore thumb.

John

__________________

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

10-21-2008, 11:00 PM

10-21-2008, 11:00 PM

|

#22

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Fellow Campers

First off thanks for the help. Greatly appreciated.

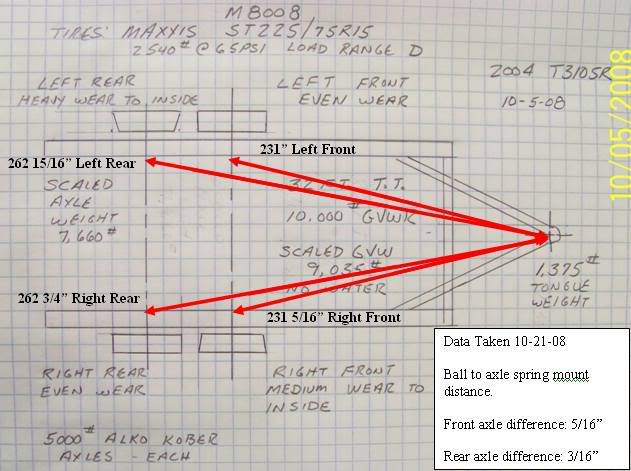

This past weekend measuring is up off the ground and no load. I was trying to figure out why the left front tire is wear so even and very little and the left rear is shot. The 2 on the right side have a level of wear with the front being the 2nd worse. I know weight adds some more accurate readings for camber but I have 1 to many things not right to get to just camber. So here take a look.

To keep the wording down, I’ll do this in pic’s. They tell more then the words anyway.

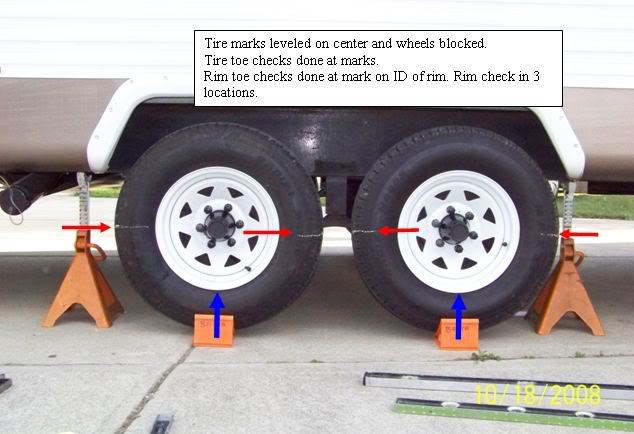

First was a toe check. I did this 2 ways, off the tires and off the rims as I did not trust rubber to be as exact, but both tell me I have a tow OUT condition.

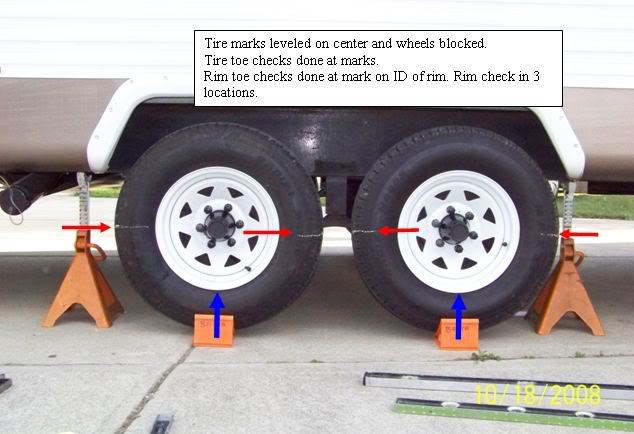

First I marked the tires level and blocked them.

I also checked that the axles where parallel to the frame on all 4 locations so the numbers would be more even.

Then from tread to tread in the same spot.

Then I did the rims in 3 places per axle and use 2 sliding U channels and a C clamp. Extend pole, lock in place on rim, take out and measure.

Here is the data

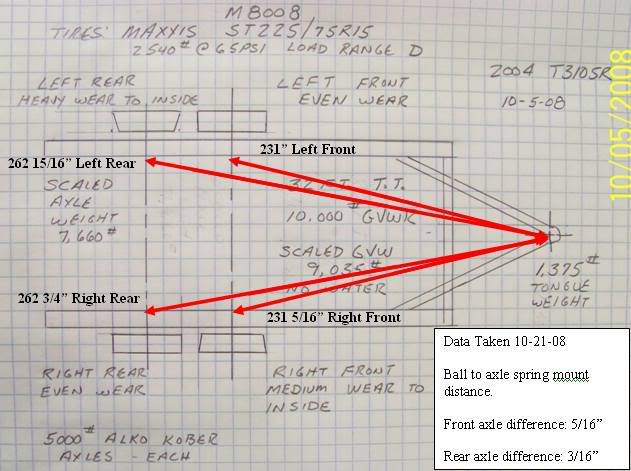

Next was an axle alignment check. This time I redid this and took a more repeatable approach. This did not turn up good news. Note: If the axle stub has a intentional bend to it, this would not show up under this method. Seeing the numbers I really question how this was set up the 1st time at Lippert.

I put an extra ball I have up in the coupler, leveled up up in 2 direction and had a scribe line in the middle of the nut.

The I picked a spot on each axle will repeat and the tape measure not fall off. It is the saddle welded to the axle tube where the U bolts hold it on

Then I pulled a steel tape tight and read off the 4 numbers.

Here is the data. If this is to be exact or at least within welding tolerance +- 1/16”

I have 1 problem here to start with.

After seeing this I wanted to do a bushing wear check to see if it could explain that big a difference. I have wear yes, but it does not explain that axle un-parallel issue.

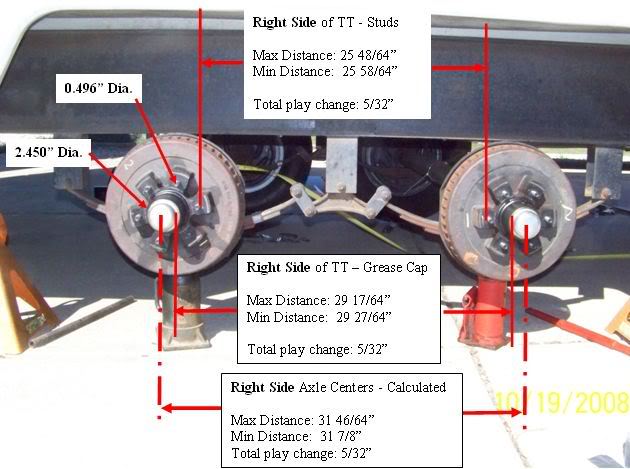

I used a method of ratchet straps to pull all the play in and then flipped the strap to pull it out Put an indicator on the end of the spring in the direction of travel. This give me total bushing play numbers in the direction of travel.

And here is the data

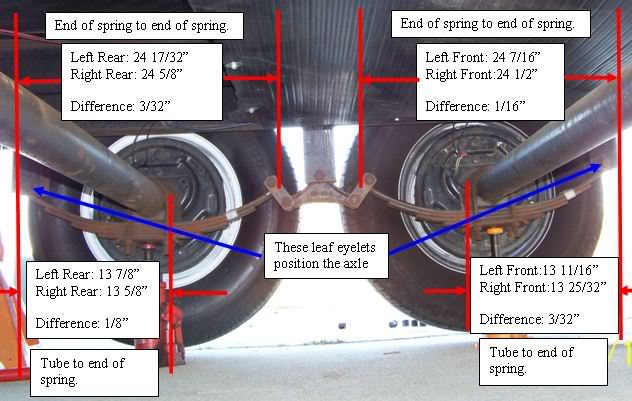

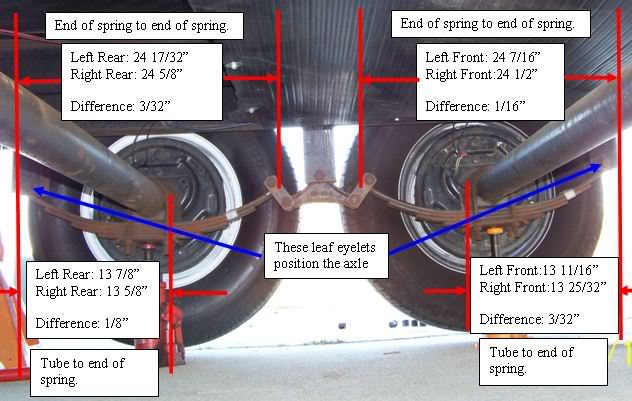

Next was, well how accurate are the springs themselves in relation the axles as the hangers might not be in the wrong spot. My way of thinking is the end hangers are what locates the axles to each other, not the equalizer. The end of the spring that is not tied to the equalizer is keeping the axle held put, right or wrong it is holding it in that location.

I used a combo square and level to get repeatable numbers.

I also measured the overall spring eye holes. The spring are made to a tolerance of something and they are not that accurate.

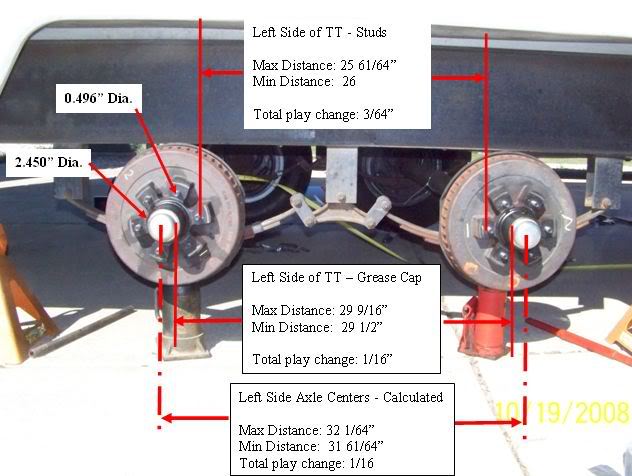

I also did an axle center check as this is what really counts. Have problem here too.

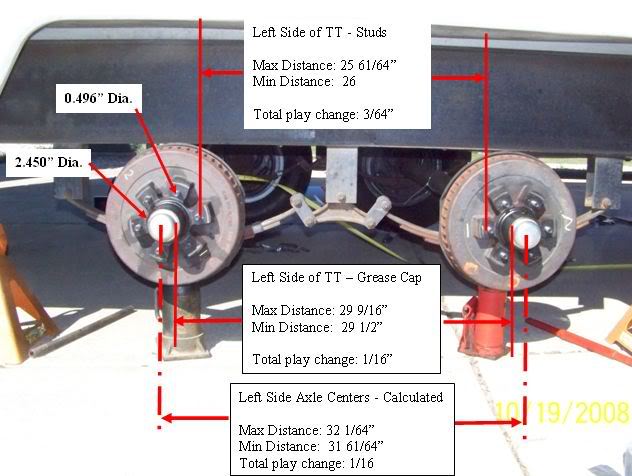

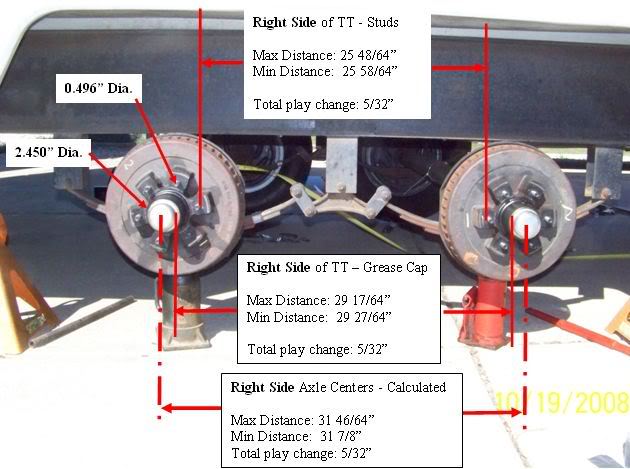

Since there is play in the connections, I pulled all the play out in both directions again using the ratchet straps. Then I used a square to measure between the grease caps and the brake drum studs.

Play pulled outwards

Play pulled inwards

The square allowed me to level up the top studs with the scale and the head on the bolt OD. Then did math to find the centers.

Here is the results/ NOTE: I messed up the min and max words...sorry The numbers are right. To much editing to go back and change

There was still the issue of is the left rear axle stub bent? I have convinced myself it is not or at least to tolerances that I “think” will not make a difference.

Here is the process

I pulled the brake plate so I could get to the axle. Both linings are wearing even so it is not bent on the drum side of the plate.

Then I used a 4 foot level along the tube with spacers and projected out to the axle stub and used some math to determine the bearing diameters are only off 0.018” from the axle tube. And some of this I’m sure is in the setup I have. So the axles is good.

I also found that the axle stub does not penetrate very far into the tube. See here the brake wires come out of the hollow tube between the U bolts.

So now armed with all this, does the un parallel axles, the toe OUT, the camber all add up to the left rear axle being so far out of alignment with the front. Well almost all of it. I can get 1/4” of it from just the axle not being parallel to each other and the heavy toe OUT. When the bushing wear on the right hand side of 5/32” comes in, it is against me, then yes it will tip the rear axle even more. Here is just the axles being out of parallel.

I will let this soak in and create a summary in the next day or so. Since I have so many things that do not look right, I believe I have a compound problem creating the wear.

Again I still need to get axle position specs with tolerance on what each factor does to tire wear.

Thanks

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

10-22-2008, 11:22 AM

10-22-2008, 11:22 AM

|

#23

|

|

Senior Member

Join Date: Aug 2007

Location: New York

Posts: 404

SUN #385

|

JohnB:

As usual, a superb job of investigating a problem with precision! I'm glad that you did this yourself as I doubt that you would have gotten this kind of information if you had taken the Sunline to a shop.

By methodically measuring all the aspects of the axle relationships it sounds as though you have a classic case of "tolerance stack". This may be more difficult to deal with than if it were a single component such as a bent axle. On the other hand, maybe the axle can be bent by an alignment shop to accomodate the tolerances. At least now you have a good idea of what the problem really is so you can go about correcting it.

__________________

Rick

2007 Ford F150 FX4 Supercab 4x4, 5.4 FFV engine, 3.73LS.

|

|

|

10-26-2008, 08:23 PM

10-26-2008, 08:23 PM

|

#24

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

To those following along I have some things to add. I still do not have this solved but getting closer.

I have found installation spec's for how square the front axle is to be in relation to the center of the trailer.

It is listed as + /- 0.5 degrees from center. I will now do some math and determine what measuring tolerance that is as measured diagonally from the tow ball to each side of the axle at the same exact spot.

Also is how parallel the front axle is to the rear axle. It is to be with 1/16". I know I'm in trouble on this one.

Camber is set in most axles at the axle factory to match the weight rating of the axle. I could not yet find an angle loaded and unloaded at the brake drum to confirm if what I have is right or not.

Here is the source with some other good things about axles. See page 20

Dexter Applications Manual

And here are 2 other good reading sources. See page 7 of the PDF for trailers. These are on Semi's but principals are similar.

Goodyear Total Vehicle Alignment

Hendrickson Semi axles setup manual See pages 9 - 11 on the PDF. It shows and talks about the thrust angle and scrub angle of the axles not being square to the frame.

I have added up my towing mileage this year since January. It is down from normal but it is 2,792 miles to be exact and I have burned up the left rear tire. The left front is showing perfect even wear. Rotating I cannot see how it will fix this root problem. The 2 wearing ones on the right side can be helped by rotating but the right front has early signs of heavy wear like the left rear just not as advanced.

The wear "looks" like a camber issue, but I'm suspecting an incorrect thrust angle can do this as well.

I was on the hunt today to find a computer aligning shop in my area and so far it is 2 hours away that does TT's. The local guys I have to do phone calls to and will get to them as work time permits.

I also found this neat new thing from Dexter in 12 x 2" brakes. http://www.dexteraxle.com/nev_r_adjust Dexter has come out with self adjusting brakes that can be upgraded to what we have in the field on 12" brakes. Yes you have to buy the whole plate but next time I do a brake job, these will be in serious consideration.

For those who may not have read all of this what started all this anyway?

What drove me to all this is 2 things.

1. I am going to do the wet bolt bronze bushing upgrade, add shocks and a Trailer Aire equalizer.

2. Add 5 new tires as mine are past the 5 year mark, actually some are 2002 tires and I have cracks starting in the treads.

So I started looking close at the tires and then OMG... that left rear one is shot. And the other 2 on the right are showing ill health when I look close. With that type of wear I was not going to put 4 new tires on and burn them up too. The 5th is the spare.

I have 5 times the mileage on my smaller TT still in the shed not sold and all 4 tires are even wearing and I do the same 180 turn in my yard.

For reasons I have not yet figured out, the left front tire is showing perfect even wear. Which really throws this whole thing up in the air. There is a combination in there that works.

So I'm now quandering before I put any of the upgrades into the axles I have until I sort this out as they may go in on new axles.

I'll keep you posted. Anyone with insights on toe limits and camber limits as measured loaded and unloaded for TT’s please pass along.

A letter to Dexter and Al-Ko will be coming soon. I'll post any results I find out.

Thanks

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

12-22-2008, 09:38 PM

12-22-2008, 09:38 PM

|

#25

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Fellow Campers following this post

Here are some updates on my tire wearing saga. I have written a somewhat detailed letter to 3 different axle manufactures within the last week about my issues and if they can supply installation specs with tolerances. The hope is I can then tell which are out of spec and causing my problem. However I have hit them all it seems in holiday shutdowns so I may not know much until after the holidays.

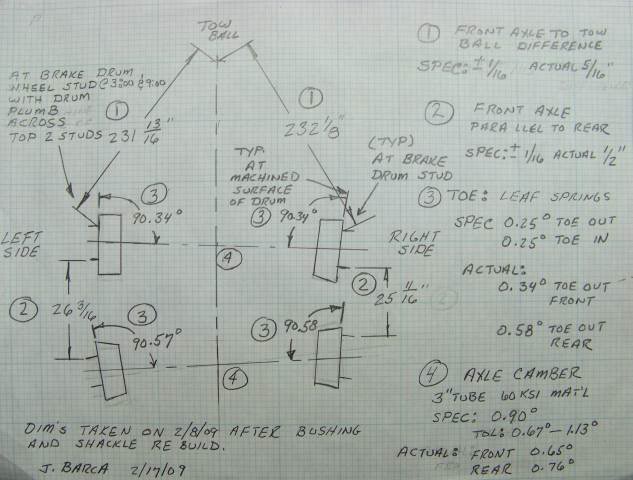

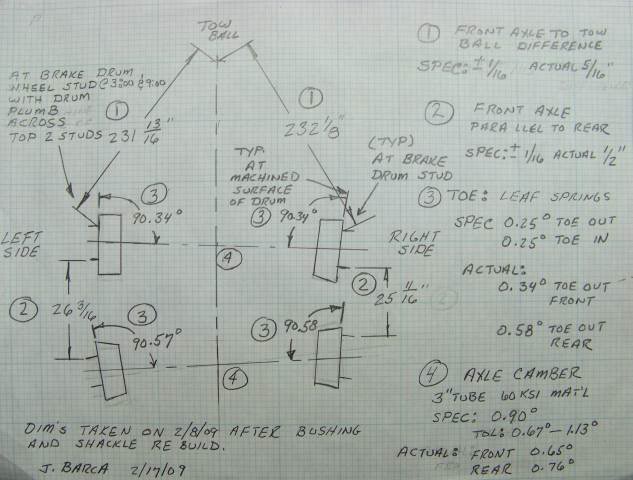

I have summarized the 3 largest problems I believe I have here on this one hand sketch.

I see at least 3 large problems.

1. Tow ball to front axle is not equal distances. I have 3/16” problem here.

2. The rear axle is not parallel to the front axle. Due to the play in the system this can greatly vary. The worst it is: 0.293”, nominally it could be 3/16”. This is a problem.

3. I have a very large toe “out” problem on both axles. It comes out to be 0.34 degrees toe out. This is a large problem.

These 3 problems all create a high degree of scrub angle to the road just eating up tires. The one tire not wear bad, the left front, but fluke the out of align front axle turn the toe out condition to almost running with no toe. That one tire I’m lucky on.

The axle alignment I have figured out how to correct by making special lower spring holding plates to slide the axle along the leaf spring to put it in the proper location. This and a total spring/equalizer bushing rebuild.

The toe out condition still has me baffled on how both axles can be messed up the same amount and so far out. To date I cannot find anything bent to cause this. I have speculation that the spring mounting saddles where welded on wrong and the axle was rotated back slightly then welded to the saddle. This would tip the front of the tire open on a pre bent cambered axle and could at least cause this high toe out condition. This I have yet to prove out and to figure out how I would go about correcting it. One method being buying new axle tubes, or cutting off the existing saddles and putting new on or something else the axle manufactures comes back with. This one has me stumped right now.

In doing more research I have come across a level of alignment specs. And an actual manufactured method of how you can adjust axles on a trailer. It is an adjusting device that takes place of the spring mounting saddle and has an adjuster to it. So you can actually adjust the axles for proper alignment. If you go to page 26 on this Al Ko catalog http://www.al-kousa.com/pdf/hdcatalog.pdf It shows alignment tolerances and the adjusting mechanism. My concept of correction would be very similar.

I have also found on semi trailers that if you want the best wear ever on the trailer tires the 2 axles must be exactly parallel. Anything less then prefect equals some level of tire wear. Point is level of wear. Most camping folks are never going to get 70 to 80K miles out of TT tires for 1 reason or another but the point is, 2 axles running true to each other is what can enhance tire life. In my case I am way out of limits.

I also have yet to figure out how this set of conditions has ever gotten to be this bad. Part if of it at this point leads me to believe it was never built right on day one for reasons not yet known.

I’ll let you know what I get back from the axle manufactures.

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

12-28-2008, 11:57 PM

12-28-2008, 11:57 PM

|

#26

|

|

Senior Member

Join Date: Nov 2006

Location: Michigan

Posts: 854

SUN #115

|

Ok, I'll admit I didnt read this entire thread to get all the specifics, but one thing I can say is you engineers are tedious when it comes to your measurements and diagrams....LOL

As soon as I saw the first picture that you drew on the lined piece of paper, I thought "WOW, that the same tire that I always have problems with!"

We've had 3 blowouts and every single time it's been that left rear tire. Anytime I look at that tire, its warn differently than the other 3? I've asked numerous people to check out the axle, the bearings and the rim itself even trying to swap out the rim to make sure it wasnt that.

I'm wondering if it's something to do with the way the camper drags that wheel when turning or cornering or if we just have a couple of lemons!

Let me know what you figure out, and when I'm not browsing the forum at 2am, I'll come back and read this in it's entirety to see what you came up with.

|

|

|

02-23-2009, 09:39 PM

02-23-2009, 09:39 PM

|

#27

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Fellow Campers

Here is an update.

I finally made it thru to Dexter to get actual axle alignment specs and tolerances. So I have confirmed just how bad off I am... I have the classic case of just about every alignment setting wrong except camber. Out of 3 axle manufactures, Dexter was the only one to respond to my requests directly. I even tried Alko who Eman had good service with and nothing.

A few weekends ago I rebuilt the suspension with new bushings and an EZ Flex equalizer. I can now measure a more true misalignment as all the suspension play is gone.

Last week Monday I contacted a local RV dealer listed as an AlKo service center. I explained my problem and if they have equipment to align axles. They themselves do not and there services deal more with AlKo sending them new axles to install on a TT under warranty. However they did contact AlKo on my behalf and I at least connected with some who would get back to them and then me. AlKo themselves do not bend align and suggested an alignment shop or Axle Inc in Elkhart to purchase new axles. This process took an entire week, but at least I was moving forward. They also have a slightly different toe spec then Dexter.

Today I contacted Axle Inc and within 10 minutes I had 2 new axles on order heading to my house. They suggested a slightly heavier axle, a 6,000# in place of a 5,200# and it only cost $19 more for the heavier axle tube. Each axle tube is $120 plus freight. $101 if I wanted to keep the same 5,200# ones I have. So if all goes really well, this Friday 2 new axles tubes should show up at the house. If not it will be 2 weeks as AlKo is shutting down 3 days for inventory. They make up each axle to order.

To bring the technical side up to date, I have now confirmed by 3 different methods my axles have severe tow out and both ends are toe’ed. They had to have been made wrong from day 1.

See here I did measure the rear axle to a 9 foot straight edge and found both ends to be the same toe out.

Positioned and clamped a 9 foot straight edge along back side of axle tube. Adjusted straight edge to be parallel to brake drum studs on both sides within 0.005” so straight edge is parallel to brake studs.

Using a square head protractor to the straight edge to measure both left and right sides.

To gain more accuracy, used square head against protractor head and used feeler gage to determine gap. After doing do trig calculations on feeler gage distance:

Left side drum is 0.565 deg to straight edge in a Toe Out condition.

Right side drum is 0.581 deg to straight edge in a Toe Out condition.

Tried to determine if axle was bent in relation to the straight edge. I could not find a very large distance change along the full length of axle tube. Left side, center and right side. Most I can find is 1/64” difference along length of axle tube as shown being measured in this picture.

I also did a CAD layout to determine how much bend would be required to straighten the front axle at

Front axle = 0.34deg toe out on both ends = 0.304” at the center bent to the rear of the TT.

Rear axle = 0.57 deg toe out on both ends = 0.430” at the center bent to the rear of the TT.

There is no way those axles are bent in the center that bad as viewed from the top. And seeing how much bend they would need to correct, I decided that it might be more then I would want bent to correct. So at this point I will start with fresh new axles and make adjustable saddle mounts like AlKo offers on there larger axles so I can dial the alignment in perfectly on the front axle to the tow ball and then the rear axle to the front.

Here is the new present condition alignment with rebuilt and tight bushings. The alignment actually became worse when I rebuilt the suspension as now that everything is tight, I can see just how out of whack the mounts are and the axles themselves.

For those wanting to know what I’m up to on the axle adjusters I did not create this idea, just adapted it to fit my axles setup. There is an actual manufactured method of how you can adjust axles on a trailer. It is an adjusting device that takes place of the spring mounting saddle and has an adjuster to it. So you can actually adjust the axles for proper alignment. If you go to page 26 on this Al Ko catalog http://www.al-kousa.com/pdf/hdcatalog.pdf It shows alignment tolerances and the adjusting mechanism. My concept of correction would be very similar. Only problem is it only seems to be offered on larger axles.

Here is what I am up to. Here is the adjuster fab’ing in process

What the adjusting brackets look like

And the 2 flat plate to go on the opposite side that do not adjust. The to flat plates will be put between the axle seat and springs to take up the height difference on the adjusting side. They will also be heavy tack welded to the axle seats so they do not move. The spring pin hole will be fit tight to the plate to make a good positive fit.

Here is how they will go in. 1st what is there to start with. No adjusters.

Then a threaded plate will be perfectly fitted and welded in the axle seat. This one is not yet fitted. This will be welded in when I have everything out in the open so no heat get’s to the spring.

Then the adjuster plate will go between the axle seat and the spring. The spring bolt will pilot a hole in the adjuster to be a good fit. This will give me +- 1/2 “ of adjustment. I will drill the spring hole with the adjust in the middle of the adjust. So I should only have to do final tweak with these to get about perfect axle alignment.

I’ll keep you posted on the progress.

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

02-24-2009, 08:19 AM

02-24-2009, 08:19 AM

|

#28

|

|

Senior Member

Join Date: Aug 2007

Location: New York

Posts: 404

SUN #385

|

JohnB:

My initial post and "knee jerk" reaction to your problem was that the axles may have been incorrectly manufactured when the axle stubs were welded to the tubes. Apparently that seems to be the case.

I know one thing for sure: I'll bet that the new axles are going to be VERY carefully checked by you when they arrive!

__________________

Rick

2007 Ford F150 FX4 Supercab 4x4, 5.4 FFV engine, 3.73LS.

|

|

|

02-24-2009, 09:24 PM

02-24-2009, 09:24 PM

|

#29

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Quote:

|

Originally Posted by Hematite

|

Rick, "you got that right"   Until this saga I never gave TT suspension that much thought. Now it is all I think about…, well almost. Warm weather camping is now high on the thought list.

Once I get the 2 old axles out of the trailer, I will pull the brakes and everything off and use the 9 foot straight edge to compare to the spindles. I will find out what is messed up with them. Curiosity now has the best of me to have to find out what is wrong.

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

02-25-2009, 05:08 AM

02-25-2009, 05:08 AM

|

#30

|

|

Senior Member

Join Date: Sep 2006

Location: Pennsylvania

Posts: 347

SUN #62

|

John this may not be your issue but I just thought I would tell you this little story. my camping buddy bought a brand new forest river salem and after just 400 miles of towing his tires looked like yours,one front and the catty corner rear worn,he called stoltzfus the selling dealer about the issue and they said it could be the tires,apparently carlisle had a run of bad tires,upon checking serial numbers on the tires this was not the case,stoltzfus was unable to get his trailer in to look at for several weeks so he asked me if I would help him take some measurements to see if something was bent our maybe installed wrong from the factory,what we found was differences of up to a half inch in axle positioning from side to side,so he called stoltzfus and asked them about these differences and stoltzfus said that a half inch is nothing,I said to my buddy how about we rotate the tires putting the good tires where the bad tires where and readjust the hitch(he has the dual cam setup)so we done this and he has since put about 2000 miles on his trailer and the tire wear has gone away.we think what was happening is that he actually had a slight bit of sway going on but he did not feel it because the dual cam was fighting it but yet it must have been enough to cause the wear,or maybe just rotating the tires fixed it but I highly doubt that.any way I hope you get your issue straightened out.atleast when you are done you know your axles will be right on.

__________________

05 sunline 267sr

01 F-250 V-10 4x4 Lariat supercab SB auto 4:30 LS

draw-tite 1200# trunnion wd,friction sway control,prodigy

happy camping Rich,Maryellen,Josh and Jake

https://www.campingpa.com/

|

|

|

02-25-2009, 03:26 PM

02-25-2009, 03:26 PM

|

#31

|

|

Senior Member

Join Date: Mar 2008

Posts: 351

SUN #549

|

Quote:

|

Originally Posted by JohnB

They suggested a slightly heavier axle, a 6,000# in place of a 5,200# and it only cost $19 more for the heavier axle tube. Each axle tube is $120 plus freight.

|

Well that ain't bad at all! I bet it would be darn close to that to have somebody pull on it on a rack.

Glad you are making progress on that issue, John. I like those adjusters too. Keep us posted on the progress and good luck!

- Frank

__________________

|

|

|

02-25-2009, 09:12 PM

02-25-2009, 09:12 PM

|

#32

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Quote:

|

Originally Posted by rich2500

what we found was differences of up to a half inch in axle positioning from side to side,so he called stoltzfus and asked them about these differences and stoltzfus said that a half inch is nothing,

|

Rich, thanks for the note. A key learning in all this that I have found is TT axles and mountings are not very precise. The misalignment problem is pretty big in the industry. Why? I do not know. With a small portion of time they can be made quite close to being in very good alignment. But it takes some time and I guess time is money when you are pumping out hundreds of these things. It is like why don’t they just install bronze bushing and a greaseable pins from the factory??? In those qty’s it is pennies.

If Stoltzfus actually meant that literally that a ½” is acceptable, well neither Dexter or Alko states that. Both company state +- 1/16”.

If you read up on semi trailer alignment, which I found a lot of reading on, there is big money in replacing tires. There they preach to shoot for zero misalignment if you want the best wear possible.

After the time I have put into what I have now, I will shoot for zero misalignment, but even that I cannot get as the brand new bronze bushing kit I installed even has play in it. And as you can see from my last diagram, it will not take much to get better then what I have now….

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

02-25-2009, 09:24 PM

02-25-2009, 09:24 PM

|

#33

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Quote:

|

Originally Posted by frank

Quote:

|

Originally Posted by JohnB

They suggested a slightly heavier axle, a 6,000# in place of a 5,200# and it only cost $19 more for the heavier axle tube. Each axle tube is $120 plus freight.

|

Well that ain't bad at all! I bet it would be darn close to that to have somebody pull on it on a rack.

Glad you are making progress on that issue, John. I like those adjusters too. Keep us posted on the progress and good luck!

- Frank |

Frank

Yeh I thought the same thing. After I figured out how much I had to actually bend these things to correct the toe, I wondered if I really would want them afterwards.

So yes it will cost me about another $75 to $100 but I have new axles that I can check to make sure they are right before I install.... and they will have a warranty on this to make sure they are right.

If I ever buy another new TT, I know for sure 1 thing that I will check before it ever rolls off there lot. Just stick a tape measure on the hangers to the ball and criss cross the hangers will tell you real quick how good or bad you have it to start with. And a toe check across the threads can happen quickly to. Camber you can just look at the axle tube under load. If it is straight or negative, well there are issues.

I hear you have your new golf cart batteries on. Gee no pics? That is a way in the future upgrade, but I start collecting ideas early... Sounds like a good topic for a new post

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

02-26-2009, 04:59 AM

02-26-2009, 04:59 AM

|

#34

|

|

Senior Member

Join Date: Sep 2006

Location: Pennsylvania

Posts: 347

SUN #62

|

If Stoltzfus actually meant that literally that a ½” is acceptable, well neither Dexter or Alko states that. Both company state +- 1/16”.

I think what stoltzfus was saying is that it's normal in the rv industry to see differences of a half inch without tire wear issues,which I disagree with because I do alignments at work so I know the importance of an alignment being correct but like you said John rvs for the most part are slapped together as quickly as possible to get them out the door and like you also said John that with the standard rv suspension it would be next to impossible to get the axles with in a 16th of an inch.

__________________

05 sunline 267sr

01 F-250 V-10 4x4 Lariat supercab SB auto 4:30 LS

draw-tite 1200# trunnion wd,friction sway control,prodigy

happy camping Rich,Maryellen,Josh and Jake

https://www.campingpa.com/

|

|

|

02-26-2009, 09:27 AM

02-26-2009, 09:27 AM

|

#35

|

|

Senior Member

Join Date: Mar 2008

Posts: 351

SUN #549

|

Quote:

|

Originally Posted by JohnB

I hear you have your new golf cart batteries on. Gee no pics? That is a way in the future upgrade, but I start collecting ideas early... Sounds like a good topic for a new post

John

|

Pics coming soon! I promise!

The battery replacement was an emergency (late fall trip, battery "seemed" fine prior, got there and found battery @ 8V) - quick trip from the state park to Sam's to pick up a pair of batteries.

I've been pulling a bunch of wire, so I'll have a big update soon. With a little luck, I'll be outside working on it today.

- Frank

__________________

__________________

|

|

|

|

|

|

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)

|

|

|

| Thread Tools |

Search this Thread |

|

|

|

| Display Modes |

Linear Mode Linear Mode

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Sunline Discussions

» Recent Sunline Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rick

Rick

Linear Mode

Linear Mode