|

|

11-18-2012, 09:18 PM

11-18-2012, 09:18 PM

|

#1

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

ST Tire Failure Analysis (Lots of Pics)

This summer I had a tire failure, 3 actually in all by the time I was done. If you are into the details of tire failures or just want to learn about tire failures, this is one type of tire failure. This is a little long of a post, but there are lots of pics to go with the words and some background.

I caught the first failure here in my yard doing axle maintenance. When I jacked up the camper to put it on jack stands, my left rear tire would not clear the ground on the normal stand height. H’mm OK what’s up?

I looked at the left rear tire and it looked more round across the face than I remembered. Still did not know what the issue was at this point.

I jacked it up some more and started to take the tires off. I took all 4 tires off and I could see one tire, the left rear looked different. It was more curved across the face of the tire than the rest. Laying it on the ground it showed up more not be square to the sides.

Here is a normal one

After comparing the other 3 to this one rear left I measured the OD of the tire. Yup, it is 1” larger in OD circumference. OK something let loose inside this tire.

I put this bad tire aside, finished up the axle work and put the spare on. I then tried to figure out what was wrong with this tire. Looking on the outside I really did not see anything much that was wrong with it other than about 180 degrees around the outside, the tire progressively was getting larger in OD up to a high spot then starting coming back down. Whatever was wrong with it created an out of round tire.

I demounted the tire and looked inside. Nothing really looked wrong to me inside. I happened to have a fellow RV buddy who is a retired tire engineer who has done tire failure analysis most all of his career. We hooked up and he told me how to section the tire and send it to him. So here is how we did this.

He told me how to cut out the side walls. I was shocked you can cut up a side wall this easy. There is inherent danger in doing this. Heavy gloves and a sharp knife is a must. Once you start cutting it out it sort of unzippers.

Now the other side. A new blade for the next cut.

Now I had a donut. The hard part is cutting through the steel wire in the tire. Ideally you do this on a vertical band saw with a progressive tooth blade. The rubber wants to bite and grab the blade. I did not have a large enough vertical band saw so I used a Sawzz All. Here one really has to clamp this thing down or the rubber will grab and start shaking the saw violently. You do not want any blade pinch as the rubber bites into the blade. Need to back flex it to keep it pulling apart as you cut. I clamped it to some old saw horses and cut it apart.

I marked with the center of the high spot so he could back into it. I also put that high spot in the middle of the sample.

Now I looked at the cross section. Well nothing real exciting at the 90 degree point from the high point that I could see, but again I'm not a tire engineer either to really know exactly what I'm looking at.

So I curled up the sample to fit in a box I could UPS to him. Here it is.

I sent him the tire and then started to investigate if I did something wrong to cause this failure. I always check tire pressure and run max cold side wall pressure at the start of every trip. I even have my own small compressor in the truck if I need it. So under inflation was not the problem.

I do not tow faster than 60 mph. I do not need too, big truck or not this is a safety limit for me. So I was not overrunning the tire 65 mph max speed rating creating excess heat. As FYI, Ohio has a 55 mph towing speed limit.

I use white tires covers when the camper is stored at home. I can say the first year they were only 50% covered until I have my present tire covers in place. There really was not much tire cracking. No side wall cracks, some very fine cracks in tread cracks and there was a number of stone cuts in the valleys of the treads.

These tires are 3.5 years old at this point made by Denman. They where made in Mexico. Denman was a big heavy equipment tire manufacture here in Ohio and known for quality tires. Do not know why the factory was in Mexico unless they may have subbed out the manufacturing of ST radial tires as the heavy tires (road graders, construction equip. etc) were made here in Ohio to my knowledge. They did end up selling the company after I bought my tires and changed the ST Express radial to an overseas import tire like most of the other US companies have to offer lower sales cost.

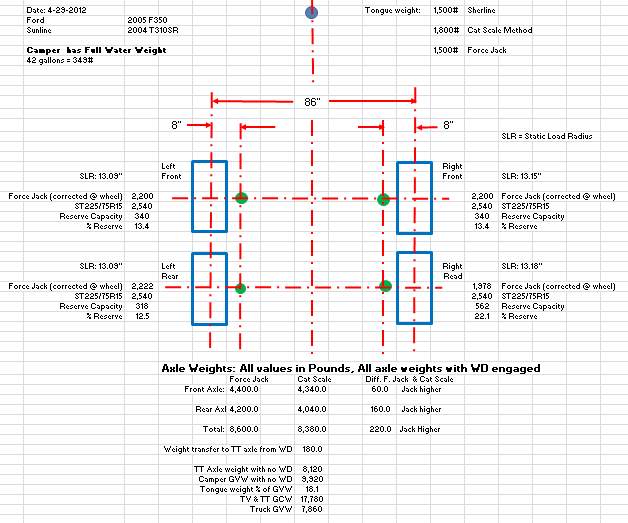

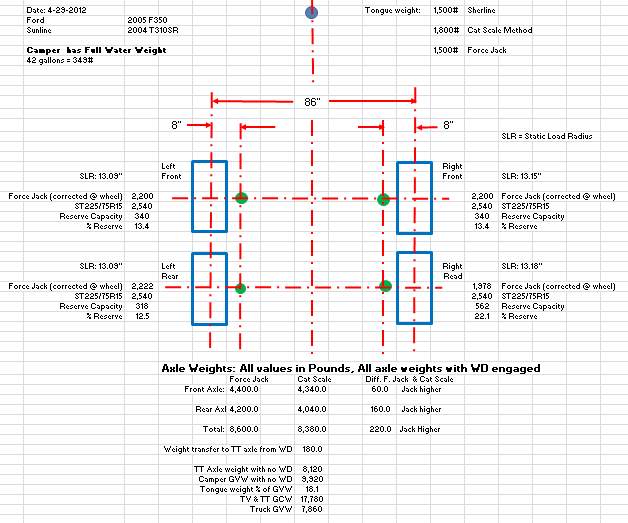

Next was weight. I had not been to the scales in about 1.5 years and I added some upgrades. So I loaded the camper with stuff for a campout and full fresh water as we do haul water to some camps. Went to the scales and weighed each axle with WD engaged. I could not get each wheel position at the scales so when I came home I used my force jack to get each wheel position. Here is the weight chart.

The failed tire location has 12.5% extra tire capacity or 318# from max load. There is some error in this data as my force jacked weighed a little heavy. It did however show me that the 4 tire locations are different. The front axle was pretty equal, the rear axle very different. My fresh tank sits right over the front axle which may have had something to do with the front being more even. At this point, weight did not seem to point to a glaring problem.

Since I could not find anything wrong, yet anyway, I bought a new Maxxis tire for the spare and we headed off on vacation. My tire buddy also was on vacation so he did not yet have my tire done.

On vacation I was 800 miles from home on the NYS Thruway and while gassing up, OMG… This tire right side rear tire does not look good. Dang, it looks like the failed one. So we pulled over in the truck lot and took it off and put the spare on. Yup, it let go too like the 1st one.

I was lucky a 2nd time I caught the failure before it let go. If you are going to have to change a tire on the road, the NYS Thruway makes a good changing spot… OK so now I have no spare…. I’m thinking of where I can get one when I get to my Mom’s house?? Well…. No luck finding one close by. We did make it home OK. Another 800 miles.

When we made it home I was already working on changing tires to LT tires. When I jacked up the camper to take off the ST’s, OH boy, another one…. The tread was bulged. This tire would not even roll correct it wobbled so bad it would fall over.

So I dodged a 3rd bullet. I could not see this when it was on the camper, only when I took the weight off. The damage did not yet progress far enough or it was not out in the open where I could see it.

Soon my tire engineer buddy was done investigating the 1st tire I sent him. The tire failed for what is called “detachment” or what is nick named sometimes “slipped belts”. It is where the tread separates where the steel belts are in the tire tread from the main tire. Basically the tire unbonded itself inside the tread. Here is his analysis pictures.

He sectioned the tire sample I sent him and knowing what to look for started to see clues of the problem. You can see small separations at the yellow arrows.

His description was; “Cut 1 was my initial cut away from the identified bulge area. There are small detachments identified. If this was all that was found in the tire it would not be a serious issue.”

Then he sectioned again and he found the entire area let go.

His description was; “Cut 2 location was identified by careful measurement of tread depth and I found a location with more wear than in other areas. The large detachments between the belts on both shoulders can be seen”

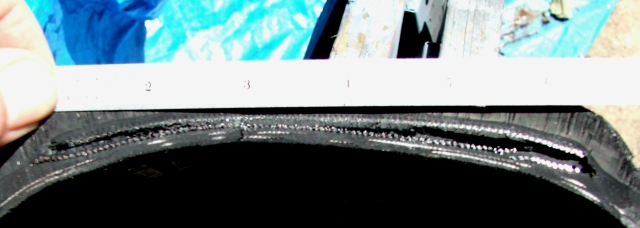

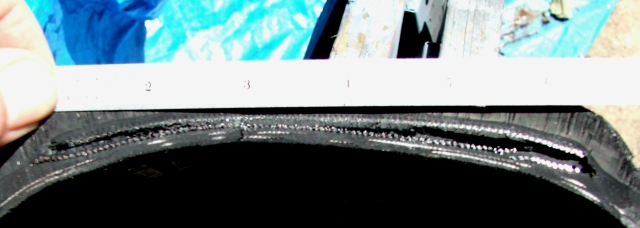

Here is his scale pushed down in each end measuring the detachment separation length.

His description was; “Detach 1a & 1b show the length of the detachment to be over 11" long”

His description was; ” Detach 2a &2b show the detachment on the opposite shoulder to be about 2" long”

And this one really shows the detachment separation.

His description was; “Detach Width shows the width of the two detachments relative to the tread width”

I asked him how did this happen? His response:

Why detachment?

There are a number of things that can cause this. They would primarily be a breakdown of the rubber that coats the steel. This could be due to a manufacturing error or simply the selection of a lower strength rubber which cannot tolerate the forces applied to the tire. Only lab testing can determine that. Sometimes detachments can be initiated by tread cuts or punctures but that does not seem to be the case of the tire I inspected. Detachments are one of the more difficult conditions to analyze as there is a need for a lot of additional background information and data.

From this investigation I have a perfect case to file a report with the NHTSA as I used the tires within the ratings. I have since filed 3 complaints, 1 for each tire. I’ll create a post on how to do this filing. It is the only way we as RV’ers can help this cause of trailer tire failures become more known to the right people who can help.

There is now a growing understanding that for tandem trailer applications that a 20% more tire capacity reserve is needed to help hold up to the service of a multi axis trailer. In my case I am towing heavy, l not overloaded, in relation to my tire capacity. When I upgraded I targeted to get as close as I could to the 20% reserve at the heaviest loaded tire and I upgraded to LT tires. While LT tires may not be for everyone, knowing your weights of each tire location and where you are in relation to the tire capacity reserve is something you can do. You can also not tow over 65 mph on ST tires, keep them at max side wall cold pressure at the start of each trip and use white tires covers over them when the camper is in storage.

Hope this helps someone in the future.

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

11-19-2012, 07:28 AM

11-19-2012, 07:28 AM

|

#2

|

|

Senior Member

Join Date: Mar 2009

Posts: 249

SUN #809

|

John, very interesting stuff. Some of us would simply replace a bad tire and not ever think about it again. You're a little (ok, a LOT) more thorough, which benefits all of us.

When I bought my fiver I paid for a "hidden option" (not on the build sheet) to upgrade to Goodyear G614, G-rated tires. They are awesome. But they are incredibly expensive, almost $2k for a set (235/85-16). After seeing so many junk tire blowouts and the damage they cause, I feel like this was money very well spent.

__________________

__________________

Jeff, Laurie, + kids

Three time former Sunline owner

2011 Big Horn 3670RL Fifth Wheel

2012 Chevrolet Silverado 3500HD D/A DRW, Classy Chassis Conversion, aka "Garage Queen II"

Hensley Trailersaver BD3 Air Hitch

|

|

|

11-19-2012, 06:10 PM

11-19-2012, 06:10 PM

|

#3

|

|

Senior Member

Join Date: Nov 2012

Location: Tennessee

Posts: 146

SUN #4578

|

JOHN,: GOOD REPORT. I had quality control experience in the Military supplier venue.. Also a partial Ford employee during the Explorer / Firestone "AT" recall / change over... & a prior Class "A" coach owner.. There was / is a SIX year life span for Class A tires reguardless of the mileage. We had little usage, but lots of sitting & had two different tires blowouts on the rear on different local trips. ... Yes I see your comment your age is at the 3 1/2 year mark.. Do not know what the expected life on your mexico tire. ?? . If that series is dis-continue,, then other pre-mature wear was reported... Almost like a two year Battery full replacement, partial refund on a sliding scale for extra months, etc.. ... As a recent classic RV buyer this does call the benefit of better side wall , load rating to tires... Originally from the TROY area ,off the NY Thruways... I read on the vintage posts of buyers going out of state for oldies & hooking up & towing home on very old ,/ small wheels. . AGAIN , GOOD PICs.

__________________

|

|

|

11-20-2012, 10:15 AM

11-20-2012, 10:15 AM

|

#4

|

|

Senior Member

Join Date: Jan 2011

Location: Florida

Posts: 1,279

SUN #1830

|

JohnB, Could the belt separation have been started by the compression chocks that fit between tires? Or maybe bumping up onto a board with sharp edges for leveling? What might seem like a insignificant "bump" or compression might be the start of separation. Especially if the manufacturer used lesser quality materials. Doesn't it seem strange to see a complete set of tires fail at the same time in the same way? If not use then what about the construction of the tire causes separation in one spot on the circumference? Is the separation at the start of the belt wrap?

Knowing where the weak spots are and what happens there might not show the straw that broke the camels back.

jim

__________________

Beverly & Jim

Sebring, Florida

1991 T-2363 Solaris

|

|

|

11-20-2012, 09:22 PM

11-20-2012, 09:22 PM

|

#5

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Jeff, Thanks for the good words. I never thought I would have this tire issue and I really got it bad... Good thing I caught it in time before they let go. And yes I needed to know if I did not do something wrong, so I dug in to learn and try and rationalize it in my head. Tire failure on a vaction away u from home can really create great havoc.

I truly believe the reserve capacity is what is a big part of the problem for a tandem axle setup. Every time I turn going down the highway much more then 15 to 20 degrees, I can see black rubber on the road from turning. It is just the tandem wheels dragging around a corner.

The folks with the new spread axles setup have it even worse as the axles are so far apart. While it will tow more straight it comes with a side effect of more tire scrub in a turn. I really question this setup as a long term solution with the tire issue we now are faced with.

Sunline was good to us to at least install running gear and tires that can hold up the entire GVWR. While this is not 20% reserve, it does help. Some brands figure the truck is holding the tongue weight so they can down size the axles to just fit max load of the tire. By the ratings they just fix but have very little to no reserve capacity.

The lack of tire reserve is becoming more talked about when we are talking tandem axle trailers.

See this from Discount Tire. They are preaching the 20% reserve over the heaviest loaded wheel. Trailer Tire Facts - Discount Tire

Some of the camper manufactures are starting to offer larger tire reserve. Your Heartland is one. But is was a hidden option. If you did not know enough to dig for this you would not of got it. But they at least offer it.

It seems Artic Fox is also now up sizing their tires. In 2007 we where looking at a 29V or a 30U before we bought the T310SR. In 2007 AF put ST225/75R15 D load range (2,540# ea) on a 29V or a 30U and the GVWR was 11,700#. That is the same tire my Sunline had at a 10,000# GVWR.

Here see the sticker off the 29V

When Mr Tweety and Tweety bought their 2012 30U Fox, AF upgraded the tires and lowered the GVWR. They now have ST235/80R16 load range E tires (3,420# ea) and 10,400# GVWR. And this is now standard. AF got on the stick and is starting to do something about the problem.

The issue still in the RV industry is to accept this across the board and make it a requirement.

It is becoming more known now, trailer tires need higher reserve capacity. The ST tire needs all the help it can get.

Thanks

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

11-20-2012, 09:31 PM

11-20-2012, 09:31 PM

|

#6

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Quote:

Originally Posted by Split

Originally from the TROY area ,off the NY Thruways..

|

Split, Thank for the good words. I do not really know why Denman discontinued the ST Express Radial. The original founder sold the company shortly after I bought my ST Express tires. The new owners then discontinued the radial ST Express and brought in a China manufactured tire offered at a lower price. Was it to make more money or what?? Good question. Since they now went bankrupt we may never know.

Troy NY. Yes I know of it. Use to live south of Albany in a town called Greenport, outside of Hudson. We use to haul fresh produce to the Menands market about every night during the month of September. Know the I90 to I787 split well. Use to call that area, spaghetti junction. If you knew where you where going, it was easy in and easy out. If you where new to the area.... you could be going in circles and off to places unknown....

Thanks

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

11-20-2012, 09:56 PM

11-20-2012, 09:56 PM

|

#7

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Quote:

Originally Posted by Jim-Bev-2363

JohnB, Could the belt separation have been started by the compression chocks that fit between tires? Or maybe bumping up onto a board with sharp edges for leveling? What might seem like a insignificant "bump" or compression might be the start of separation. Especially if the manufacturer used lesser quality materials. Doesn't it seem strange to see a complete set of tires fail at the same time in the same way? If not use then what about the construction of the tire causes separation in one spot on the circumference? Is the separation at the start of the belt wrap?

Knowing where the weak spots are and what happens there might not show the straw that broke the camels back.

jim

|

Jim, Thanks for the note. Made me do some more thinking.

The wheel chocks, a possible thought for sure. After thinking more on it I cannot see the chock creating any more load on the tire than sitting on the ground. In my case the axle is pressing down by approx 2,200# from camper weight per tire. The tread goes flat from the weight as seen at the tire patch on the ground. The expanding wheel chocks are not creating a force that large and I can see I am not flattening the tire very much to almost none at the chock. So I say the wheel chock is a very low possibility after thinking through this.

My boards I use for leveling all have 45 degree chamfer cuts on them. They roll up fairly easy. I actually had to chamfer them as when cut square the board would slip in place trying to roll up on it. I did the chamfer a long time ago on the old Maxxis tires the camper had on it when new. So the Denman's all saw the chamfer.

Why did 3 tires all go within a close proximity of each other? A good question. I directly quizzed my tire engineer buddy to make sure I did not some how cause this. He stated several times, no. He did quiz me if I curbed the tires, towed over 65 mph, over loaded them, ran over pot holes, all which did not happen. While a pot hole may have come, it was not 3 tire locations. I'm in control of the speed, weight and curbing.

The conclusion I came to is application of not enough tire capacity reserve and or a manufacturing problem of the tire. The tire unbonded itself inside. Did application of not enough reserve capacity create the heat that casued the unbonding? Materials in construction? These tires where not the cheapest ones when I bought them. The company had high marks for quality. My truck tires ride over the same pot holes if there are any, they are also not ST tires.

Thanks for the added thoughts.

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

11-21-2012, 05:29 AM

11-21-2012, 05:29 AM

|

#8

|

|

Senior Member

Join Date: Jan 2011

Location: Florida

Posts: 1,279

SUN #1830

|

thanks JohnB,

My question came up because of looking at the "homemade" chocks. When I looked at how the boards were compressed on the tires it seems they pinched them, by drawing the board together. That would cause a bulge between the boards as they were tightened because the boards came together instead of being pushed into the tire. The "store bought" metal locking devices, because of their cam action when locking, look to extend more into the tire towards the axle instead of drawing the tire pads together in a pinching motion.

The way the homemade compression chocks add extra "flat spots" to the tread is why I haven't used them, yet. If those chocks are used for any length of time the tire should have not only the one flat spot but three. The one where the tire meets the road and two more on each tire where the boards meet the tires, however so slight. While one flat spot doesn't harm the tread so much, the three spots being so close to each other and the reverse flex of the belt between each flat spot might be more than is good for the tires. This might also be exaggerated once the chock is removed and heat of the rolling tire is added while the tires try to return to their preferred round shape. Throw in all that stress and then add a few turns traveling out of the campgrounds to add sideways scrubbing and it could be a problem, in my minds eye.

But like you said the strain put on the tires by the homemade chock is not enough to do any harm. I think I'll still just use regular chocks since it seems easier to me to throw them into place instead of cranking and adjusting on my knees since I don't have so much of a motion problem with my little TT. I even sold my "If this campers rockin, don't bother knockin" sign.

Good luck solving your problem.

jim

__________________

Beverly & Jim

Sebring, Florida

1991 T-2363 Solaris

|

|

|

11-21-2012, 08:17 AM

11-21-2012, 08:17 AM

|

#9

|

|

Senior Member

Join Date: Jan 2007

Location: Pennsylvania

Posts: 380

SUN #149

|

Jim.....

For what it's worth...... We've used home-made "compression" chocks for about 16+ years. We (were lucky enough) to never encounter a carcass-failure tire in those years. Of course....tread & alignment issues took their toll at times. I really tend to doubt that the homemade compression chocks were at fault.

Also....it's my impression that such chocks work largely not by compression, but by static load transfer from one tire to another,as the tires attempt to roll.

Frank

__________________

Frank Yake - Sunlines 1982-2008 TT= 2016 Casita Liberty 17 SD (NASA42-B) TV= 2017 Hyundai Santa Fe

|

|

|

11-21-2012, 02:58 PM

11-21-2012, 02:58 PM

|

#10

|

|

Senior Member

Join Date: Jan 2011

Location: Florida

Posts: 1,279

SUN #1830

|

Frank,

That is a good reference for the compression chocks for sure. I still don't feel the need to use them. Maybe my low frame height makes a difference there. Maybe the shorter jacks don't sway so much to cause us problems.

To me it still looks like the homemade chocks will pinch the belts of the tire reducing the circumference and expanding between the tire between the chock boards to at least hold them in place. Granted when the camper tries to move the movement is transferred from one tire to the other but when not trying to move the gripping of the chock that holds it in place seems a pinching action, to me but I've been wrong before.

When the tires sit on the ground the trailer weight is compressing the tire towards the axle. The wooden chocks do not seem to put the same action on the tires as when setting still but rather try to compress the circumference. It is the longitudinal pressure instead of the compression pressure that I thought might stress the belts. If not when not rolling then when rolling and the tire is trying to return to the normal circumference.

It is for sure that three out of four tires going bad on one camper has a real cause. Either use or construction. Hopefully JohnB's friend can find more issues and causes.

But like you said, sixteen years of use without problem make the homemade chocks seem fault free.

jim

__________________

Beverly & Jim

Sebring, Florida

1991 T-2363 Solaris

|

|

|

11-22-2012, 08:41 PM

11-22-2012, 08:41 PM

|

#11

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Hi Jim,

I have been doing more thinking on your concern on the home made tire chocks. Today I had some time between cooking and waiting for the kids to come over so I did some measuring and calculating. I'm trying to prove myself right or wrong in this and being open minded. I also emailed by tire engineer buddy for his direct thoughts.

There are several tire chock systems.

Several by Bal

BAL - Innovative Products for the RV Industry

The X chock

The Bal Deluxe tire chock

The Bal standard chock

The Bal single axle chock

RV trailer wheel stop with lock

There is another version, cannot find it right now, it has a cam action and goes between the tires. The contact area is very small and it rotates in place. It is considered a high end one, at least from the cost.

Now let's look at mine. I went out and measured the force today then calculated the force on the tire to bring this into perspective.

Mine are made out of 4 x 4's and the angle is cut to match the profile of the tire. I use a 1/2" drive deep socket wrench on it.

There really is not a lot of torque on mine. I measured it. 100 in. lb. or 8.3 ft lb. I used 3 different torque wrenches to make sure this low of a number was correct. It is.

Then I did some math on the torque, the angle of cut and the contact patch size the tire has to the concrete. Here is what I came up with.

The tire has a contact patch on the ground of 46 square inches. 6 3/4" long X 6 3/4" across the tread.

Now here is the chock. I tried to take this pic to show there is not much compression on the tire OD. Compare this to a flat on the concrete that is 6 3/4" long.

Now the forces.

The 100 in. lb. of torque in a 5/8" all thread rod creates 800# of force in the rod. This 800# is spread between 4 chock tire contact points, or 200# per chock face.

Due to the angle on the chock face and mechanical advantage, the tire is seeing 325# agasint the face of the chock. My homemade chocks have a large surface area of 15.5 sq. inches which comes out to be 21 psi.

The tire is pressing down to the concrete with 2,200# on 1 tire, the surface area there is 46 sq. inches or 48 psi.

The camper is pressing down creating a flat contact patch 6 3/4" long with a force of 2,200#. My wheel chock is pressing against the tire with a shape that is more close the OD. By eye, I do not see a tire radius change. The camper is pressing down 6.8 times more to the concrete creating a flat on the tire than the chock which has very little change in tire radius.

When I tighten the screw, the slack between the top chock and bottom chock is gone and there is a preload of 325# pressing on the tire. The rest is friction. The chock face acts like a brake pad so to speak and since the all thread rod will not allow the chock to spread open, the tries do not roll.

The commercial chocks have less contact surface area so the point load will be higher if the force is the same. As far as clamp force, I believe they are close to the same. They may cause more tire flex, but I think the metal will start to deflect if they try and apply too much force. They are not that heavy of a metal.

Unless my tire buddy see's something we are missing here, I'm not seeing how the chocks are flexing the tire very much at all. The tire sitting on the ground is creating a 6 3/4" long flat spot. The steel belts are flexing just like they do rolling down the road.

I have used these chocks now on 3 different sets of tires since 2003. This is the first time I had a tire failure. This is also the 1st time I have had Denman tires. I camp on average about 60 nights a year. The chocks are on the tires 60 days a year. The other 305 days a year they are sitting with a 6 3/4" flat spot from the camper pressing down on it.

After looking at the actual loads and deflection involved, I'm still leaning towards ST tire sizing/application and construction of the tire. I'll pass along anything my tire buddy comes back with. If you see something I missed, help explain what you are seeing. I'm not following how the chock can flex the belts to the point of concern.

Thanks

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

11-22-2012, 09:02 PM

11-22-2012, 09:02 PM

|

#12

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Quote:

Originally Posted by Jim-Bev-2363

thanks JohnB,

The way the homemade compression chocks add extra "flat spots" to the tread is why I haven't used them, yet. If those chocks are used for any length of time the tire should have not only the one flat spot but three.

The one where the tire meets the road and two more on each tire where the boards meet the tires, however so slight.

While one flat spot doesn't harm the tread so much, the three spots being so close to each other and the reverse flex of the belt between each flat spot might be more than is good for the tires.

This might also be exaggerated once the chock is removed and heat of the rolling tire is added while the tires try to return to their preferred round shape. Throw in all that stress and then add a few turns traveling out of the campgrounds to add sideways scrubbing and it could be a problem, in my minds eye.  |

Jim,

The force straight down is 200# in my case. That is less than me standing on the tire. Granted there is also 200# pushing up, however that is not much force to try and "pinch" the tire to the point the tire will bulge out in the center. Have you ever tried to "pinch" a tire?

Thinking on this now, I can actually measure this to see if there is any bulging going on. We are going camping on Friday and I will see if I can measure the gap between the 2 tires before and after putting the chocks on. If there is "pinching" going on, the gap between the 2 tires should change.

I'll report back on Sunday.

Thanks

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

11-23-2012, 05:00 AM

11-23-2012, 05:00 AM

|

#13

|

|

Senior Member

Join Date: Jan 2011

Location: Florida

Posts: 1,279

SUN #1830

|

Good morning JohnB,

First off, I hope everyone had a good, enjoyable Thanksgiving Day. May the rest of the holiday be relaxing.

Now to the chocks.  Seeing how the homemade chocks are made and installed it does look like the pressures should not be as bad as any other pressures the tires would be seeing during normal use.

I have installed tons of tires, but that was a long time ago when I was young and trying to hold jobs pumping gas. The pinching is a most difficult thing to do, for sure, but when adding the weight of the vehicle in one place, the positions of the chocks that are also stationary, and then add rocking forces, it all could restrict tire expansion, in my mind. Maybe the forces will be minimal at any one point but adding them together might create a larger problem.

I also noticed the tires were cross sectioned to see how the belts were coming apart. The separation/views made the defect seem to be a bullseye target area with the center still holding. Maybe if one was cut the lengthwise with the tread it could show another view of the "bulge".

Also, when looking at how tires are constructed the bulge could have been where the belt wrap came together or other of the mechanical assembly processes. Add that weakness to the cheap materials and the belts simply come apart like unfastening your belt on your pants. At the time of construction the manufacturers were restricting quality in the name of profits, maybe. Those restrictions could have been anything from materials to labor. Any of which could give faulty products and the responsibility of the manufacturer, not the end user.

As for you having so much trouble with your set of tires at one time, I would think tires that should have been rejects slipped through the system and stayed together until they were mounted on your camper instead of being spread out over many campers. Were your manufacturing codes the same?

On another note I saw on the news last night a blurb about used tires and the date of manufacture. Car tire life expectancy and date code is something that will be regulated by law to help protect the public. Used tire dealers were complaining about their business being over regulated.

Enjoy the rest of your holiday, everyone, and relax while camping.

jim

__________________

Beverly & Jim

Sebring, Florida

1991 T-2363 Solaris

|

|

|

11-23-2012, 05:21 PM

11-23-2012, 05:21 PM

|

#14

|

|

Senior Member

Join Date: Jun 2007

Posts: 263

SUN #308

|

John

Thanks for bringing up what seems to be a serious industry wide issue with tire failure. Over on the RV fourm it seems there are almost daily postings about tire failures. I believe that we are just seeing this country flooded with cheap low quality trailer tires.

I do have a question I am considering purchasing new LT tires to replace the 6 year old tires on my 2499. But I had a question about rims. Will the stock steel rims work with LT tires or will I need to buy new rims?

__________________

Hiller

2013 Montana Mountaineer towed by 2009 GMC Duramax

2003 Sunline T 267SR towed by 2009 GMC Duramax

Formerly a 2006 Sunline 2499 towed by a 2001 Toyota Tundra

|

|

|

11-25-2012, 05:50 PM

11-25-2012, 05:50 PM

|

#15

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Quote:

Originally Posted by hiller64

John

I do have a question I am considering purchasing new LT tires to replace the 6 year old tires on my 2499. But I had a question about rims. Will the stock steel rims work with LT tires or will I need to buy new rims?

|

Hi Hiller,

Odds are high your rim may not be stamped with a pressure and only a weight rating.

See this post, it can help on the LT upgrade as HenryJ upgraded his T2499 to LT's. He gave a lot of good detail to follow. There is also discussion there on rim's pressure ratings.

http://www.sunlineclub.com/forums/f7...ers-12045.html

If your rim has some markings on it to list a manufacture, that may be your only savings grace to call them and directly ask if your rims are rated for the pressure of an LT E range tire if you limit the weight to the C load range. Which would be 80 psi plus the heat up factor which may take it to 90 to 95 psi.

I have heard some folks state that the load rating of the rim is more severe than the pressure rating. I have never seen calculations to that end, only talk. In your case you are on C load range or 50psi less the heat up factor. Making a jump to 90 to 95psi is a considerable amount. I myself would not make an assumption the rim can handle it if I did not have confirmation from the manufacture. That is almost double the pressure.

In both Henry's case and mine, we both bought new rims to be able to go up to E load range. Even if I would of stayed in 15" ST's at E load range, I would bought new rims. I deal with pressure vessels at work and there are no work arounds unless they are certified. A different situation as tanks, pipe etc. and wheels are different, however there still have a pressure rating.

Good luck and glad to help more if I can. If you make the jump to LT's, drop a note in that LT post on how you came out. Your right, this tire saga on trailers is a concern.

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

11-25-2012, 07:32 PM

11-25-2012, 07:32 PM

|

#16

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Quote:

Originally Posted by Jim-Bev-2363

Good morning JohnB,

First off, I hope everyone had a good, enjoyable Thanksgiving Day. May the rest of the holiday be relaxing.

|

Thanks Jim, it was good. Had Thursday with the family and then Friday we went camping.

Quote:

Now to the chocks. Seeing how the homemade chocks are made and installed it does look like the pressures should not be as bad as any other pressures the tires would be seeing during normal use.

I have installed tons of tires, but that was a long time ago when I was young and trying to hold jobs pumping gas. The pinching is a most difficult thing to do, for sure, but when adding the weight of the vehicle in one place, the positions of the chocks that are also stationary, and then add rocking forces, it all could restrict tire expansion, in my mind. Maybe the forces will be minimal at any one point but adding them together might create a larger problem.

|

I measured the pinch…. Learned something new… Here it is. Started with the chocks uncompressed. Picked 2 tread lugs in the middle of the 2 tires (axle centerlines). I used a set of telescopes to create the distance.

Then measured. Un chocked the gap is 1.430”

The chocked to the 100 in.lb of torque, I back at the same 2 lugs, the gap is 1.383”

I made the assumption both tires expanded the same. I tried this setup 3 times and amazingly the dimensions repeated with 0.002”. The difference from un-chocked to chocked is 0.047” or each tire expanded 0.024”. Basically a heavy 1/64” or a light 1/32”, aka not much. 0.024” is about the thickness of 4 to 5 sheets of note book paper. Also to note, I did this on LT load range E tires. The next time I have my flat deck trailer out with had 15” ST’s LR D’s on it, I will try this is I remember too.

After seeing this, anytime a tire is held by a wheel chock that is actually contacting the tire, there will be some deflection. Even the loose wedge chocks that are touching the tire, if the camper pivots slightly there will be load on the chock, the OD will compress. Unless there is heavy compression by any type of wheel chock, this still does not come close to the contact patch compression on the ground under the camper weight.

After measuring the tire pinch, it now adds perspective to what league we are talking about from homemade wheel chocks. I’m not seeing this pinching as a source of belt damage. If the belts can handle the weight with the contact patch on the ground, I would think they should be able to have this very small amount deflection.

Quote:

|

I also noticed the tires were cross sectioned to see how the belts were coming apart. The separation/views made the defect seem to be a bullseye target area with the center still holding. Maybe if one was cut the lengthwise with the tread it could show another view of the "bulge".

|

Don’t know on this one Jim. Roger, my tire buddy did the work. He has done tire failure analysis for 40 years and I was following his lead. I have never been through this before. The section that held in the middle in this one spot may be the problem just did not progress far enough yet. I removed the tire before total separation.

Quote:

|

Also, when looking at how tires are constructed the bulge could have been where the belt wrap came together or other of the mechanical assembly processes. Add that weakness to the cheap materials and the belts simply come apart like unfastening your belt on your pants. At the time of construction the manufacturers were restricting quality in the name of profits, maybe. Those restrictions could have been anything from materials to labor. Any of which could give faulty products and the responsibility of the manufacturer, not the end user.

|

I agree quality is potentially part of this. The other application. Back when ST trailer tires where made here in the US, they may have over built them. More safety factor was built in and higher quality materials may have been used. To the consumer they just had no problems or at least less problems. To them that was higher quality. Now enter modern day profit wants and they try and lean the process down to the bare minimum. The tire may be in spec. , but on the bare minimum. Now the application. As I mentioned earlier there is a growing knowledge base that for tandem/tripple axles this application requires a higher degree of reserve capacity rating for the scrubbing going on in turns. Take out the use to be highrt safety factors, enter the new learning’s of tandem axle setup and we end up in tire failures.

Quote:

|

As for you having so much trouble with your set of tires at one time, I would think tires that should have been rejects slipped through the system and stayed together until they were mounted on your camper instead of being spread out over many campers. Were your manufacturing codes the same?

|

Don’t know about the reject part. Here are the date codes. All tires installed on 4-5-2009

1st tire failure on 4-21-2012: 10,614 miles, DOT mfg. date 1908 or the 19th week of 2008

2nd tire failure on 6-20-2012: 11,225 miles, DOT mfd. Date 2908 or the 29th week of 2008

3rd tire failure on 7-17-2012: 11,770 miles, DOT mfd. Date 2908 or the 29th week of 2008

The 4th tire, did not yet fail, was removed from service on 7-17-2012: 11,770 miles, DOT mfd. Date 2908 or the 29th week of 2008

Do not know what can be deduced from the dates for sure. They were having a bad quarter? Since they only go by week, hard to tell if they were all the same day or Monday and Friday tires…. In my situation I ran the other 3 tires for a short period of time before changing all of them. I had to deal with a camper ride height change on the new tires. If timing was better, I would of changed all 5 of them (spare too) after the 1st one let go. Then I would of only had the 1 failure. The last one that did not let go was not going to get the chance….

This for sure has been a learning experience.

Thanks

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

11-25-2012, 07:33 PM

11-25-2012, 07:33 PM

|

#17

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

I did get an answer back from my tire engineer buddy,

Here is his response on if the tire chocks were part of the problem with my tires. I sent pics of my tire chocks.

Quote:

|

RE tire chocks. I don't think the deflection is sufficient to cause the problems we have seen.

|

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

11-26-2012, 06:59 AM

11-26-2012, 06:59 AM

|

#18

|

|

Senior Member

Join Date: Jan 2011

Location: Florida

Posts: 1,279

SUN #1830

|

JohnB,

Glad you had a nice Thanksgiving. Good food, family and friends and a comfy chair to loosen our belts in can't be beat.

I have tried to post three times but get bumped each time. Will not try to repeat and answer each point again.

The one thing I did see was not a separation spot but a separation circle. That is why it looked like outside forces to me. The little effect of the chock and the tire setting on the ground shouldn't have done it but yet we see the circle instead of a spot.

In the end all the average person can do about tire failure is to make a report, buy a new tire and move on. Hopefully the powers that be will fix their problems and we can miss damage to our TT the next time.

jim

__________________

Beverly & Jim

Sebring, Florida

1991 T-2363 Solaris

|

|

|

11-26-2012, 08:42 PM

11-26-2012, 08:42 PM

|

#19

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Hi Jim,

Sorry about the forum bump out. It has happened to me here and other forums. Here most times for a time out the forum unhooks you. I have learned the hard way.... that if a post has any kind of length to it, I type in MS word and then cut and paste it in. If the internet unhooks or the site times out, I can paste it again.

A trick sometimes to get your text back is, use the back key in your browser. Many times it will bring the text back, then swipe it and copy to your PC scape buffer, exit out of the post, make sure the forum is still working or your logged in and create a new reply and paste the words in.

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

11-27-2012, 06:03 AM

11-27-2012, 06:03 AM

|

#20

|

|

Senior Member

Join Date: Jan 2011

Location: Florida

Posts: 1,279

SUN #1830

|

Hi JohnB,

I tried the Backspace Key with no luck.

Usually when signing in here I will check the "Keep Me Signed In" box and that stops any need to loose my sign in. That time I did not do so. My mistake, and not anyone else's.

I will use Notepad most of the time for really long posts. I will also have two pages open while typing posts. The one page is the page I'm reading, another page is the post submit page and any reference page I might use. Can be confusing sometimes.

Nobody's fault but my own and that is why I got so frustrated. Being stoopid is bad enuff but doing it repeatedly is aggravating. Story of my life.

__________________

Beverly & Jim

Sebring, Florida

1991 T-2363 Solaris

|

|

|

|

|

|

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Sunline Discussions

» Recent Sunline Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Seeing how the homemade chocks are made and installed it does look like the pressures should not be as bad as any other pressures the tires would be seeing during normal use.

Seeing how the homemade chocks are made and installed it does look like the pressures should not be as bad as any other pressures the tires would be seeing during normal use.

Linear Mode

Linear Mode