|

Hi Gary

Well, I know sheet metal, but what do you want to know about?

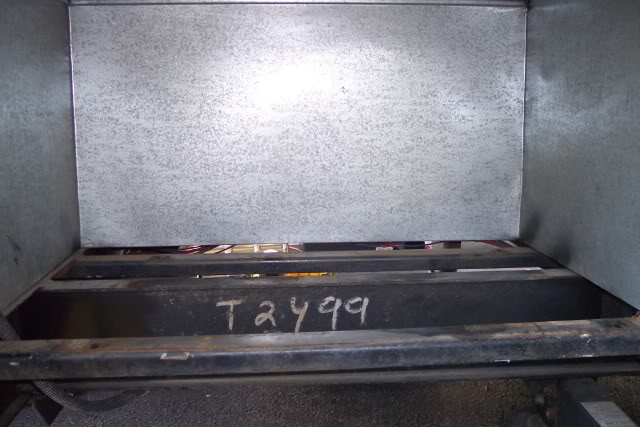

The galvanized box is what we call a sheet metal development. To make less splices you pre figure how to lay out that shape in the flat then put it in a press brake and bend it up. Depending on what you are making, there are still some seams that are welded. In galvanized it gets complex if it is pre galvanized sheet before you start. As welding messes up the galvanizing. How they do it in mass production is form it up in plain mteal sheet, weld then hit dip the end result. Then welds and all are coated.

If you do not need welded sealed seems then there are other ways to make the seams and you can use pre galvanized sheet.

If you find someone who makes HVAC duct work, they deal with this all the time. They are sort of tin knocker masters at this. A metal fab shop can also do these but they generally work on thin and thick plates where the HVAC guys only deal with duct work most of the time. The creations they make are amazing.

Are you trying to recreate this in the T310 or other applications?

John

__________________

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

Linear Mode

Linear Mode