|

|

10-05-2008, 09:11 PM

10-05-2008, 09:11 PM

|

#1

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

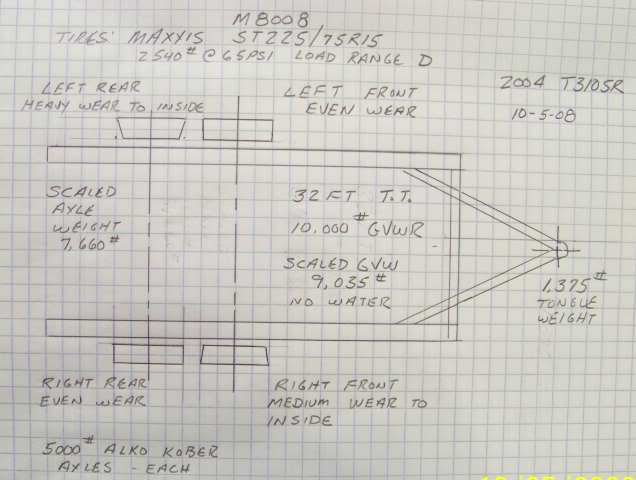

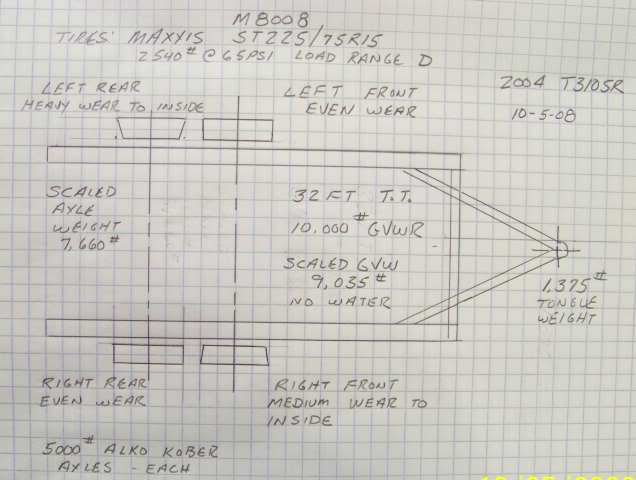

Tire Wear Pattern-Tandem Axle TT (Pic's) Where to look next

Fellow Campers.

I have a tire wear problem. I’m due for new tires due to age/start of tread cracks however upon inspection today I have a wear problem on 2 of my tires. And the odd thing is they are different axles.

The Left rear has heavy wear, the left front is nice and even wear and lot’s of tread left.

The Right rear is nice and even wear and lot’s of tread left, the Right front has medium wear.

Both wearing tires are wearing inwards toward the trailer, and straight across the tread. The outside has a lot of tread depth the inside already to the wear bars. These are the original tires on a 2004 camper.

If you know of what can cause this please expand on it and give pointers where to look. This kind of wear points to something being off, the tires are scrubbing, but I have not yet found it. The rest of this post is in pic’s to help get the point across.

Here is a sketch of the wear and the camper setup

This is a fairly std tandem axle setup

Here is the inside. Note there is a sq tube that spans the front and rear hanger area across the frame. Note: Only the rear sq tube is shown here.

And there is a gusset welded on the center hanger to the main I bean frame rail for support.

OK now to the wear patterns

The Left rear. The worst. See wear pattern even across the tire, tapering to the inside.

A straight on shot

A shot of left rear at ground

A shot of left rear at top

Now the left side but the front tire. Here there is even wear and lot’s of thread. A straight on shot

Left front top shot

Now to the right side. The Right rear has even wear and lots of thread. Note this is the same axle as the left rear with lots of wear. A straight on shot

Right rear top shot

Now the front right. This is wearing as well. Again tapered wear across the tire towards the inside. Just not as much as the left rear. A straight on shot.

Right front top. You can see the sips are worn different on the inside as it is worn more.

So now I tried to see if the hangers where not equally spaced on both sides. There are some differences. I do not know the tolerances these where made to is the numbers or OK or not. While different, I can’t figure out why both tires on the same axle are not wearing if these differences mean something??

Here is the right side.

Here is the left side. I have 1/8” total difference and about 1/16” on the hangers. I also noticed the hangers are not exactly 3” wide. I did not check the actual pin centers, yet anyway. While the hangers might be slightly different widths and different left to right, the pivot pins is what is locating this. I assume these are welded on a jig based off something.

The center left hanger is also welded on twisted. See here. Again while this does not look right, I can’t figure out how it in and of itself will cause this wear.

The inside of the hanger

The outside of the same left center hanger

And a pic of the left rear hanger that looks normal like the rest of them.

Any ideas?

I will measure from the ball center to the front hangers on left and right to see if that is correct and even. Ran out of time. But again if the axles are mounted wrong in relation to the ball coupler, I would “think” both tires on the same axle would wear. The camper tracks straight and inline behind the truck. There is no dog tracking.

I’m hoping someone has bumped into this and can help point to root cause.

Thanks

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

10-05-2008, 09:22 PM

10-05-2008, 09:22 PM

|

#2

|

|

Moderator

Join Date: Dec 2006

Location: Michigan

Posts: 6,155

SUN #123

|

Hi John,

Sorry I can't help much, but my 2363 had that problem with only one tire, the LR. I sold the trailer with that problem. I ran into the previous owners one time this summer, and I mentioned it to them. They explained they noticed it too, and had replaced it a couple times. I never put many miles on it, but I swapped the tires with the ones on the 2251 and it started to wear the one on the LR still.

The previous owners estimated they put like 30k miles on it, going to the west coast often.

I'd be interested to know if there is a solution though.

Jon

__________________

__________________

2007 T-286SR Cherry/Granola, #6236, original owner, current mileage: 9473.8 (as of 6/18/21)

1997 T-2653 Blue Denim, #5471

1979 12 1/2' MC, Beige & Avocado, #4639

Past Sunlines: '97 T-2653 #5089, '94 T-2251, '86 T-1550, '94 T-2363, '98 T-270SR

|

|

|

10-05-2008, 09:53 PM

10-05-2008, 09:53 PM

|

#3

|

|

Senior Member

Join Date: Aug 2007

Location: New York

Posts: 404

SUN #385

|

Hmm, I would almost have to think that the spindle assembly on the problem wheel is not welded 90 degrees perpendicular to the axle tube. Presuming that the backing plates aren't bent try to measure from side to side to see if this is the case. If this is the problem, I don't know how you could cure it

__________________

Rick

2007 Ford F150 FX4 Supercab 4x4, 5.4 FFV engine, 3.73LS.

|

|

|

10-05-2008, 10:08 PM

10-05-2008, 10:08 PM

|

#4

|

|

Senior Member

Join Date: Mar 2008

Posts: 351

SUN #549

|

John,

That certainly looks like a wheel bearing issue to me on those two tires.

Get the axle up off the ground, grab the tire one hand each at 12 & 6 o'clock and push with one hand pull with the other back and forth. You should have almost NO play. There could be a teeny tiny bit, but it usually should be so little that you can't notice it. Comparing a good one to a bad one, you might feel the difference.

It's actually easier to diagnose bad wheel bearings in cars - they have a very distinct sound pattern.

Could be a bum bearing, but it is entirely possible they were installed too loose - they may not have been "set" when they were assembled last. If they were installed too loose, they may now be damaged, but you might get lucky. I'd pull the bearings, wash the bearings out, clean the races and inspect. If they look goofy, I'd change the bearings & the races, they're cheap enough.

When the bearings are gone or they are too loose, the downward pressure of the axle makes the top of the tire tilt inward, hence the wear pattern you are seeing on those two.

If the axles were slightly out of kilter, you usually get a real funny almost herringbone looking mark diagnonally across the tires.

- Frank

__________________

|

|

|

10-06-2008, 05:27 AM

10-06-2008, 05:27 AM

|

#5

|

|

Moderator

Join Date: Dec 2006

Location: Michigan

Posts: 6,155

SUN #123

|

Quote:

|

Originally Posted by frank

That certainly looks like a wheel bearing issue to me on those two tires.

|

I put all new backing plates and bearings on my 2363 and the problem was still there.

Jon

__________________

2007 T-286SR Cherry/Granola, #6236, original owner, current mileage: 9473.8 (as of 6/18/21)

1997 T-2653 Blue Denim, #5471

1979 12 1/2' MC, Beige & Avocado, #4639

Past Sunlines: '97 T-2653 #5089, '94 T-2251, '86 T-1550, '94 T-2363, '98 T-270SR

|

|

|

10-06-2008, 05:31 AM

10-06-2008, 05:31 AM

|

#6

|

|

Senior Member

Join Date: Apr 2007

Location: New York

Posts: 1,846

SUN #264

|

These are some general questions, and not specific to JohnB's towing:

When making a relatively tight turn, like onto a side street from a main road, maneuvering into a driveway or campsite, turning in and out of a gas station, etc. have an unequal effect on the tires?

On the inside of a tight turn, does one tire track smoothly while the other scuffs its way around the turn? On the outside of the turn, do both tires track relatively smoothly (compared to the inside) due to the larger turning radius? Or do they scuff in reverse?

Do a lot more of us have this problem, and just haven't noticed it to the degree that some have?

I remove my tires when winterizing, and store them in an unheated shed. When they go back on in the spring, while I don't have a rotation plan, it's highly unlikely that they'd end up back on the same hub each year. All 5 of my tires show the same wear as John's, but to a lesser degree suggesting that I have the same problem, but can't determine which axle on which side is wearing the most.

An observation... I'm thinking it is very unlikely that this is a Sunline specific problem. If we were to walk through a campground looking at any manufacturer's tandem axle TT's, I suspect we'd begin to see the same wear patterns over and over again. And that would suggest that it's in the nature of the beast to have this uneven tire wear.

__________________

'12 F250 4x4 Super Duty PowerStroke 6.7 diesel

2011 to present: '11 Cougar 326MKS

1999 to 2011: '99 Sunline T-2453

SUN264 * Amateur Radio kd2iat monitoring 146.52

|

|

|

10-06-2008, 07:39 PM

10-06-2008, 07:39 PM

|

#7

|

|

Senior Member

Join Date: Mar 2008

Posts: 351

SUN #549

|

Quote:

|

Originally Posted by Sunline Fan

Quote:

|

Originally Posted by frank

That certainly looks like a wheel bearing issue to me on those two tires.

|

I put all new backing plates and bearings on my 2363 and the problem was still there.

Jon |

Jon (and John!),

If the bearings on the offending wheels checked out, my next move would be to check the camber (and toe), would need to obtain the correct alignment specs from the axle manufacturer. Although it's possible it's 0/0, it's quite likely not. Anyway, these can be corrected with the installation of alignment shims.

Quote:

|

Originally Posted by Steve Collins

These are some general questions, and not specific to JohnB's towing:

When making a relatively tight turn, like onto a side street from a main road, maneuvering into a driveway or campsite, turning in and out of a gas station, etc. have an unequal effect on the tires?

On the inside of a tight turn, does one tire track smoothly while the other scuffs its way around the turn? On the outside of the turn, do both tires track relatively smoothly (compared to the inside) due to the larger turning radius? Or do they scuff in reverse?

|

Steve, I'm no suspension expert, but I have scratch built a couple of axles. Here's my take on your questions.

During turns, the wheels should track relatively smoothly. Because each wheel is independant, each tire/wheel can turn at different speeds. The only time I could picture there being any potential scuffing would possibly be under extremely tight movements, almost jack-knife like. These movements are (hopefully) done slow-speed and not too often anyway.

Quote:

|

Originally Posted by Steve Collins

Do a lot more of us have this problem, and just haven't noticed it to the degree that some have?

I remove my tires when winterizing, and store them in an unheated shed. When they go back on in the spring, while I don't have a rotation plan, it's highly unlikely that they'd end up back on the same hub each year. All 5 of my tires show the same wear as John's, but to a lesser degree suggesting that I have the same problem, but can't determine which axle on which side is wearing the most.

|

It's certainly possible (and I'd say quite probable) that others experience the issue and don't notice it.

You may want to keep track of "what goes where" for a while and see if you can narrow down the issue any. If it is a correctable issue, there's no sense in prematurely wearing down the tread.

Quote:

|

Originally Posted by Steve Collins

An observation... I'm thinking it is very unlikely that this is a Sunline specific problem. If we were to walk through a campground looking at any manufacturer's tandem axle TT's, I suspect we'd begin to see the same wear patterns over and over again. And that would suggest that it's in the nature of the beast to have this uneven tire wear.

|

It may be common, but I personally would not be willing to accept it as "just the way it is."

- Frank

__________________

|

|

|

10-07-2008, 12:41 AM

10-07-2008, 12:41 AM

|

#8

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

To All:

Thanks for responding. Between every ones comments I can put some puzzle pieces as to what “might” be occurring. Steve’s comments really jogged my thought process.

I have this same post running on RV.net. Tire wear on RV net Here is one on a fifth wheel It seems this is more common then one might think. But for me I need to figure out what it is and I may be able to fix something.

Frank, shims to align, How/where? Everything is welded to the frame?

Some folks on RV.net saw what looked like a weld crack. I never saw this.

First the weld. I’m away for work this week but I have zoomed in on the pic’s. See here. The “crack” I believe is a weld undercut. I will confirm. I missed it.

Next the bent axle ideas. I did inspect the TT last year when I bought it. It was no way this worn across the tires. This thought process has allowed me to dig back in picture time and by luck find that left rear tire at different stages of wear this year.

First, yes these are 5,000# Al-Ko axles.

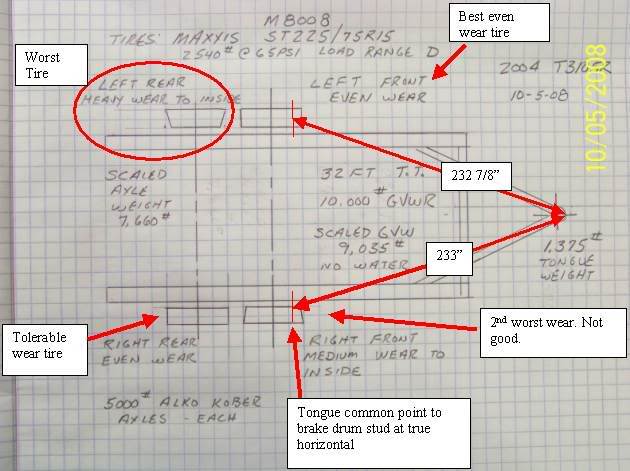

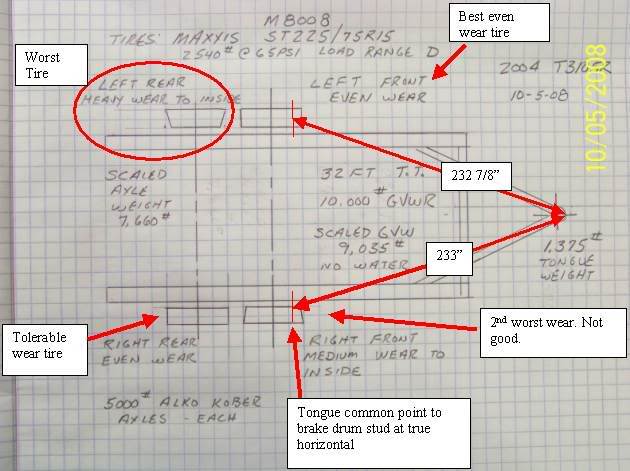

Next is, well do I have a bent axle? Or 2?? Maybe. Look at this wear pattern. Left rear and right front are worn. This is what Steve’s comments sparked off. This looks like a left turn wear pattern. The Left rear is scrubbing real hard and the front right. Those 2 tires skid most of a hard left turn. The front left sort of more pivots around, still scuffing but not as bad as the rear. The rear right has the largest arc to follow and more rolls.

And I “think” I know how this “might” have happened. On a tandem axle TT, when you turn hard the axles do some really heavy moaning and the tires flex hard. A hard sidewall ST tired is for sure needed for this high flexing going on.

Left turns are more common then right turns in my case. Our CG’s are made for the most part to back in on the left. It is easier to see on the drivers side. And there is one unique thing to my situation. My drive way. I have to do a hard 180 turn in my yard to turn around. This is on concrete. During the winter/spring months the lawn is too soggy and I will loose the camper in the lawn, so I have to do this turn. In the summer I use the lawn. Here are a few pics of this turn.

My K2500 before the F350

Now the F350

And the TT in It’s resting place

I see the black on the concrete from the tires. It’s expected but it means scrubbing is going on.

Here is a progression of time this year from assorted pic including that left rear tire. Remember this camper is 1 year old now for us from last September.

Jan. 2008. I have a force jack I can weigh the camper in my yard with.

See the sips of the tire. The inside of the left rear is still there intact.

Now progress to March 2008. A pic under the slide

Closer

And even closer. The inner tread was still there in March.

There is now about 2,000 miles since March. I went to the M & G and to a long haul up to Bristol IN. August 12th, wear pattern now being seen on left rear inside

And now Oct 5

The question now is, did I bend something doing a 180 turn? I still have 1,000# more GVW to go before hitting GVWR on the TT and the axles are 10,000# rated and I only have 7,660# on them? Are these Al-Ko’s that thin? What do you do if you ever turn around in a parking lot?

This is what I will do next to confirm if I have a bent axle or messed up bearing. Suspect bent axle as I adjusted the brakes about 2 months ago and they spun nice. I would of found a gross wobble then.

-- Jack up TT and put frame on 4 jack stands on level concrete pad. Ahead and rear of axles.

-- Let suspension go to limp neutral position.

-- Place an even height block of wood under each axle by the springs so now both axles now parallel to the level concrete. The axles and equalizer should now be right for measuring.

-- Use 2, 4 foot levels horizontally and put spacers on them against the rims. If the left rear and front right are bent, it should show up.

-- Do a tape measure check from ball center to front hanger brackets, LH and RH on an angle to check that the hangers are even distance from ball.

Report back findings. This might take me a few weeks with work being so busy.

If anyone has any ideas/comments please keep then coming.

Thanks

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

10-08-2008, 02:27 PM

10-08-2008, 02:27 PM

|

#9

|

|

Senior Member

Join Date: Aug 2007

Location: New York

Posts: 404

SUN #385

|

JohnB:

I did see the weld "crack?" in the first pictures but I thought that you saw that at that time. I'm glad that someone mentioned that to you.

Making that sharp a turn and scrubbing rubber off on the concrete may be the actual problem. Hopefully, it's nothing more than that. Tire rotation will take care of that.

Good Luck!

__________________

Rick

2007 Ford F150 FX4 Supercab 4x4, 5.4 FFV engine, 3.73LS.

|

|

|

10-08-2008, 08:37 PM

10-08-2008, 08:37 PM

|

#10

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Rick

What appears to be a crack, I think is an actual weld undercut. I won’t know until Friday when I get home.

On the tire wear, the more I’m reading and now thinking, something is bent. And I do not know if tire rotation will ever cure that ill. From putting the puzzle pieces back together of my various camping pics, In March of 2008 that rear tire was fine with about 1/4” tread depth straight across. Now in October, it’s shot. The wear bar is showing and in some places worn into it. .

The kids call Cindy and I “Camping Animals” now but this year I have not camped as much as I normally do or wanted to. That wear from good tire to a shot tire I think occurred over 3 to 4,000 miles. At that rate I would burn all 4 tires up in about 2 years if I rotate.

If doing a U turn on hard pavement caused this, I’m not impressed with these Al Ko alxes. What would I do if these where triple axles?

I have to find root cause first, then I will figure out what to do.

Thanks for the thoughts. Those new tires I was wanting to get in the spring are now in my very near future. After I find out what is up with these axles. I will change out that left rear tire with the spare that has never seen the road yet Friday when I get home before going camping this weekend. The spare is going to get replaced anyway due to age so if I burn it up until I get this fixed then well OK as I now will not tow with that one left rear tire. I do not want need to post my tire blow out experiance...

Thanks

John

PS Thanks for the wish of good luck. I'm thinking I will need it.

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

10-08-2008, 09:16 PM

10-08-2008, 09:16 PM

|

#11

|

|

Senior Member

Join Date: Aug 2007

Location: New York

Posts: 404

SUN #385

|

Good tire to badly worn in 3-4,000 miles?? Whoa, that is NOT good! I wasn't realizing that the wear was occuring that rapidly! Uh, you'd have to buy a tire company to keep yourself in tires at that rate!

Since you probably parked the T2499 in the same spot, previously, did you have any kind of issues like this?

I have Alko Kober torsion axles but I'm going to check the tires tomorrow. I've never noticed unusual wear before but I think that this

Sunline only has about 2600 miles, total, at this point.

I still have to suspect that the spindles are misaligned, particularly in view of wear that is that rapid. I can't imagine that turning and parking is doing this but I'm not an expert.

It seems to me that if the axles were perfectly square to the frame and to each other, but those 2 wheel spindles were not welded square to the axle, that this problem would occur exactly as it is. If you want, I'll go to the local dealer and pose the question to him to see if he has any knowledge about this type of problem.

I do know that in just researching various RV problems I have seen posts where axles were replaced under warranty because of some defects on various TT's.

Hey, if I can do anything to help you out with this problem, count me in. You, as well as others on this Forum have been a great deal of help to me. I would be happy to return the favor!

__________________

Rick

2007 Ford F150 FX4 Supercab 4x4, 5.4 FFV engine, 3.73LS.

|

|

|

10-09-2008, 01:06 PM

10-09-2008, 01:06 PM

|

#12

|

|

Senior Member

Join Date: Aug 2007

Location: New York

Posts: 404

SUN #385

|

JohnB:

I just spoke to the local dealer about your problem. He said that depending on how sharp a turn a trailer has to negotiate, it will scrub rubber off 2 of the tires. He said it is not uncommon to have a wear pattern exactly like yours. On some trailers, because of the usage causing the problem, he has to rotate the tires to make the wear more even.

Unless there is a physical problem, like a bent axle, tire rotation may be the only answer to the problem. I think that the longer the trailer and the sharper the turn, the more this scrubbing effect will occur.

I checked my 2499 and the tires are perfectly evenly worn across the tread. I didn't expect that, but I'm pleased. I don't really make any turns sharper than 90 degrees so that may be the reason. You might try to determine the straightness of axle/ spindle relationship to be sure that is not the problem. I wonder if an RV dealer would have a wheel alignment machine to determine the straightness of the axles?

Again, good luck in resolving the problem!

__________________

Rick

2007 Ford F150 FX4 Supercab 4x4, 5.4 FFV engine, 3.73LS.

|

|

|

10-10-2008, 08:37 AM

10-10-2008, 08:37 AM

|

#13

|

|

Senior Member

Join Date: Mar 2008

Posts: 351

SUN #549

|

Quote:

|

Originally Posted by JohnB

Frank, shims to align, How/where? Everything is welded to the frame?

|

I think I stuck my foot in my mouth big time.

Most of the straight axles I've been playing with have had removable spindles, where you can shim between the axle plate and the spindle. Looking at Alko's exploded diagram earlier, it seems that is NOT the case with theirs. My apologies.

I had a friend of mine, who is a big suspension nut take a peek at this thread. He offered up the following:

- First, check the bearings for any signs of play for good measure. He believes a bum bearing would tend to wear the innermost section of the tire, and not across the face, but thinks it's worth the 10 minute check.

- Second, as you are doing, check the axles for "squareness". He believes being a little out of whack should not be an issue, that the movement in the equalizer and such should null that. However, he thinks that once you get past a point, you would see wear like you are seeing.

- He agrees that tight turns will cause that wear pattern as well, although he had reservations that you would be making that tight of a turn that often to take them down that far.

- Check camber and toe on the axles. An alignment rack is great, and soemone probably has one big enough to handle a trailer, but you can do the measurements at home no problem. Race guys do this all the time.

- He says it's a little hard to tell from the pictures, but he believes the wear you are seeing is commonly called "feathering" and is often caused by a non-square axle or other alignment issue.

Finally, when I was looking through the Alko documentation, I saw that they have a wear chart showing some common problems and their causes/solutions. This is available at http://www.al-kousa.com/pdf/alkobrochure.pdf on page 25.

Hope this helps out, John. Again, sorry for the mis-information.

- Frank

__________________

|

|

|

10-13-2008, 10:15 PM

10-13-2008, 10:15 PM

|

#14

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Rick and Frank

Thank you to both of you!  I’m humbled by both of you went above and beyond to contact others on my behalf to help with this issue. Thanks Guys.

This past Sunday I had about 4 hours to do some more investigation. Had the entire camper up on jack stands and all 4 wheels off on a witch hunt. The hunt was good, at least at finding some things. Now I have to figure out what drives what or I have a compound issue. I have to get the all pic’s sized and loaded and put in a post. Stay tuned for incoming, but for sure I do believe at least 1 axle is bent and the other out of alignment.

The next thing is to find out what are the specs of hanger (perch) placement and what camber/toe is normal and what will wear. I can find a lot out about a semi trailer, but have not yet found the right spec’s on a single tandem axle setup like on our TT’s.

Frank, the worst wheel, Left rear, when I had the tire off I did grabed the drum and yanked, no play by hand. I did not get out the indicator but if there is play in it, it is less then 0.002 to 0.003”.

Rick, the T2499 in the shed on Dexter axles, I have done 180 turns in the same yard for 3 years. All the tires are still true with lots of tread on them and wearing even. No issues.

Here are some quick pic’s from the weekend. More to come with data.

The setup. Bottle jacks only to level axles parallel on all 4 to level concrete, no weight lifting. TT up on 4, 6 ton jack stands leveling out the TT.

Yes that is 15/32” that the rear drum is out from the front drum. Bent.

There is more, I’ll wet your whistle with these tonight

Thanks

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

10-14-2008, 06:41 AM

10-14-2008, 06:41 AM

|

#15

|

|

Senior Member

Join Date: Aug 2007

Location: New York

Posts: 404

SUN #385

|

JohnB,

Nice job checking the alignment of the axles! As I suspected, there is a misalignment. I wonder if that can be corrected without replacement? I remember that, years ago, truck alignment shops would bend the Ford Twin I Beam axles to align them. Possibly an old truck alignment shop could do that to your axles? The alignment specs could probably be taken from the best wearing wheel that you have now and applied to the other spindles. Just a thought.

__________________

Rick

2007 Ford F150 FX4 Supercab 4x4, 5.4 FFV engine, 3.73LS.

|

|

|

10-14-2008, 09:38 PM

10-14-2008, 09:38 PM

|

#16

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Rick

Yes I am using the 2 good tires as a guide of what works however some things are marginal differences and without specs it hard to tell how close to the edge the good ones are or not.

For camber, they seem to bend the axels in the middle so under weight the camber comes out right from my searching the web over. That was why I was measuring front and rear axle in the middle for the amount of bow.

If the left rear is actually bent, it almost has to be right at the axle stub, as the long axle tube is straight left to right across the front which would change the toe in.

Still digging. I also have to dig to see if there is an alignment shop here in town that can handle this.

More yet to come

Thanks

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

10-14-2008, 09:49 PM

10-14-2008, 09:49 PM

|

#17

|

|

Senior Member

Join Date: Mar 2008

Posts: 351

SUN #549

|

Quote:

|

Originally Posted by JohnB

Rick and Frank

Thank you to both of you! I’m humbled by both of you went above and beyond to contact others on my behalf to help with this issue. Thanks Guys.

|

That's the least I can do, John. You always go above and beyond to help people here, and it's certainly appreciated. All the WD tips you gave me were invaluable!

Quote:

|

Originally Posted by Hematite

JohnB,

Nice job checking the alignment of the axles! As I suspected, there is a misalignment. I wonder if that can be corrected without replacement? I remember that, years ago, truck alignment shops would bend the Ford Twin I Beam axles to align them. Possibly an old truck alignment shop could do that to your axles? The alignment specs could probably be taken from the best wearing wheel that you have now and applied to the other spindles. Just a thought.

|

I have seen guys pull automotive trailing arms back into alignment as well. It is certainly doable. The only 'catch' could be that machine time exceeds the axle cost, but it never hurts to ask!

I wouldn't be shocked to find that the ~1* of camber John shows in the picture is in the ballpark. Like I mentioned before, I don't have a ton of trailer experience, but that much camber is common on an auto trailing axle for stability and tracking. Same for a tad bit of toe-in. I think the last one I did was .5* camber. But it is entirely possible a trailer axle is setup dead square. I would think (hope) that Alko could provide the alignment specs.

Sorry about the bearings, John - that sure would be an easy solution. Honestly, of all people, I didn't expect *you* to have sloppy bearings..

I think your measurement techniques should be solid, John. I did similar things when I built my last axle, and once it was finished, we got it on the car and onto the alignment rack. We found it to be dead on one side, the other side < .1* out. The guy running the rack said that's better than most stockers and he couldn't believe we built it on the floor

- Frank

__________________

|

|

|

10-16-2008, 10:05 PM

10-16-2008, 10:05 PM

|

#18

|

|

Senior Member

Join Date: Aug 2007

Posts: 280

SUN #382

|

As a big rig driver, I would highly suspect that the bend came from the high torque load put on the axles by the tight turn. During extreme jacknife manuevers, the tires will fold over on the sidewalls and scuff laterally until such a point where the tires will actually be moving in two different directions at four different speeds....I actually would be surprised if there was a bend there- I really think that it is just from the torque load under the scuff...

You can actually hear the effect of this when near a TT rear tire set goes past you on the highway. That "thwopping" sound is where the tires are unevenly worn because of this.

My immediate first thought was that it was due to tire scuff, and then I saw your pics. and remembered your setup....

I hope you can get the bend (if that's an issue) fixed, but you may be in for more issues if you keep up the tight turn. They do make castered platforms that you could pull onto that have four wheels so they can spin 360 degrees like these:

http://www.jegs.com/i/Green+Oak+Whee...16-35/10002/-1

from Jeg's. They are costly though, and you may just be better off backing up that long, long driveway. It'll mean a lot less strain on your wd setup and coach frame too.

Greg

|

|

|

10-16-2008, 10:28 PM

10-16-2008, 10:28 PM

|

#19

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Last weekend I was able to take some measurements and as promised here they are.

First is an overview of the wear as measure on the tire tread and a center of ball coupler to the front axle.

I was using the best even wear tire as a guide which was the left front. This tire was really good and even.

The worst tire wear was the left rear. Heavy wear.

The right side of the trailer has significant wear on the right front and tolerable wear on the right rear.

See here for the tire tread wear.

First my spare bought at the same time as the other 4 and never used. This is the base line on tread depth.

Now the best even wear. Left front.

And the worst wear, the left rear. Towing mileage about 4,000 miles did this.

Now the right side. Here the wear flipped. Front is worse then rear.

That wear pattern follow what I believe is out of alignment on the axles.

So I went axle checking. I jacked the rig up and put on jack stands on level concrete. I then used bottle jacks under each axle to gently lift each axle so the height at the axle end was even on all 4. This put the equalizers level.

So now I started to measure. The load is off each axle and this is the raw unstressed findings.

I tried to see if the left front and rear wheels where in line. They where not by using the wheel flange.

Seeing how far off this was I wanted to use the machined surface of the brake drum. Here I found and eye opener. Used a 36” Starett scale known to be true.

And here you can see the rear is out of align with the front by 15/32” on the Left side.

This same check on the right side showed the front drum 0.052” out of alignment.

Before pulling the wheels I did a camber check on the wheel. And then did the same recheck on the machined drum. Here is the data

Front Left on wheel = 2 deg. On Drum = 1.5 deg Best even wear tire.

Rear Left on wheel = 2 deg. On Drum = 1.0 deg Worst wear tire.

Front Right on wheel = 0.5 deg. On Drum = 0.5 deg 2nd worst uneven wear tire.

Front Left on wheel = 1.5 deg. On Drum = 1.0 deg Tolerable tread wear.

Close up on left rear

Next was an attempt at Toe in. Here I measured the drum to be parallel to the TT frame.

The data:

Left Front Drum = Front 6 29/32” Rear 6 27/32” Out of parallel = 1/16”

Left Rear Drum = Front 6 29/32” Rear 6 26/32” Out of parallel = 3/32”

Right Front Drum = Front 6 29/32” Rear 6 29/32” Out of parallel = 0”

Right Rear Drum = Front 6 30/32” Rear 6 30/32” Out of parallel = 0”

See the left rear so far out to the left front I thought maybe the axle shifted on the U bolts. But no, they did not. All 4 axles, U bolt axle saddle to brake drum plate are with 1/32”

So next was, well is the axle bent and what is the camber bending on front and rear. Used a 4 foot level and measured the center of level and tube to see difference in the center. From what I have tried to find on the web, they bend the axles in the center to put in camber in the on the ground loaded condition.

Rear Axle is 0.273” bend at center.

Front Axe is 0.318” bend at center.

Difference between front and rear: 0.045”

Don’t mind my worn steel toes…

I also checked the level on the horizontal of each axle tube to see if it was bent. Nope, each are within 1/64” of being true across 4 feet at the center.

Next I measured the hanger bolt centers to see if they where welded on right It looks like the rear hangers are 1 /4” different. The front ones are in not bad.

So what does this all mean?

Good question. The left rear wheel has issues for sure. The toe in check, 3/32” difference also follows the rear drum to front drum 15/32” out data. The left rear axle stub is pointing backwards. Which is also the way stress is coming from a left sharp turn. But I have not yet found what is bent to be that far out. It is like the machine axle stub end is bent welded into the axle tube. I did not have time to pull the brake drum but the drum spun free and had no wobble from bad bearings.

If there are any trailer alignment folks out there, opinions welcome. I also have to find the spec on the axle alignment on how far out each parameter can be. Have found for semi trailers, but not single tandem TT’s axles. Any one know of any posted on the web?

Comments welcome where to look next.

Thanks

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

10-16-2008, 10:52 PM

10-16-2008, 10:52 PM

|

#20

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Quote:

|

Originally Posted by Mooney

As a big rig driver, I would highly suspect that the bend came from the high torque load put on the axles by the tight turn. During extreme jacknife manuevers, the tires will fold over on the sidewalls and scuff laterally until such a point where the tires will actually be moving in two different directions at four different speeds....I actually would be surprised if there was a bend there- I really think that it is just from the torque load under the scuff...

You can actually hear the effect of this when near a TT rear tire set goes past you on the highway. That "thwopping" sound is where the tires are unevenly worn because of this.

My immediate first thought was that it was due to tire scuff, and then I saw your pics. and remembered your setup....

I hope you can get the bend (if that's an issue) fixed, but you may be in for more issues if you keep up the tight turn. They do make castered platforms that you could pull onto that have four wheels so they can spin 360 degrees like these:

http://www.jegs.com/i/Green+Oak+Whee...16-35/10002/-1

from Jeg's. They are costly though, and you may just be better off backing up that long, long driveway. It'll mean a lot less strain on your wd setup and coach frame too.

Greg |

Greg

Thanks. A few things

The tire wear is 360 deg all around, not a flat spot.

Strain on WD and TT frame. Have that one covered as I already knew this. One of the reasons I have a 1 ton truck and a Class V Towbeast receiver. I take the WD bars off before I do that hard turn or else the hitch will break. The truck and receiver is rated and can handle the dead tongue weight to move around in my driveway. WD bars always on while road towing regardless.

From the data I found, it sure looks like the left rear is bent back and maybe the right front. Yet I cannot find exactly where. May have to pull the brake drum to see the axle stub.

The turn dollies, thanks but I have not figured out how to use them after each camping trip that is practical. A 4 x 8 sheet of something lower friction maybe but even that is a royal pain. In the summer months I use the front lawn to turn around, but spring and winter, I'll loose the truck in the lawn. Been there did that with the T2499... So I have to turn in the yard. Backing in from the road, real dicey with the road traffic.

I know you do this with your big rig backing into some hole in the wall alley, but you are a lot bigger in the road and people stop for you.... well some do anyway.

The T2499 did these same turns now for 3 years and no issues. This new one, well may be only turned 6 to 8 times. If the turn caused it, it does not say much for these axles. What degree is too much? 180, 170, 150, 120? The rig is turning no more then 2 to 3 MPH. And yes the tires do get funky in all directions.

First I have to find what is bent, then figure out how to fix, then how to prevent again if I can ever out how it occurred.

Thanks

John

__________________

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

|

|

|

Currently Active Users Viewing This Thread: 3 (0 members and 3 guests)

|

|

|

| Thread Tools |

Search this Thread |

|

|

|

| Display Modes |

Linear Mode Linear Mode

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Sunline Discussions

» Recent Sunline Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rick

Rick

Linear Mode

Linear Mode