|

|

07-18-2008, 07:46 PM

07-18-2008, 07:46 PM

|

#121

|

|

Senior Member

Join Date: Nov 2006

Location: New York

Posts: 2,909

SUN #93

|

Henry - thanks for posting the "proposed fix" for your trailer - I just read it to Leo (who owned his own auto body shop and did a lot of frame work)....we will be contacting our welder next week with your ideas.....going on vacation in August so need to get our act together to make this repair!!!!!

Thanks again.

Kathy

__________________

__________________

Kathy & Leo SUN 093

Central Adirondacks of New York

2013 Rubicon 2900 Toy Hauler

We loved our 2007 T-2499

2010 Ford F-350 4x4 Lariat Super Crew Dually Diesel

|

|

|

07-19-2008, 10:36 PM

07-19-2008, 10:36 PM

|

#122

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,654

SUN #89

|

Hi Folks

Trying to fill in a few missing pieces of what did Sunline in 2005 that was so different then other TT manufactures with I beam frames, I continue to look at about every camper I run into now on how the frame is built. And I must say, there seems to be no industry standard way to do this. Each brand does something different and many repeat elements of the 2005 Sunline design on there 7,000# GVWR TT’s.

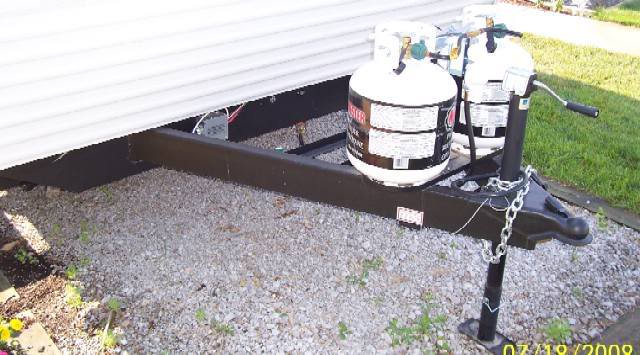

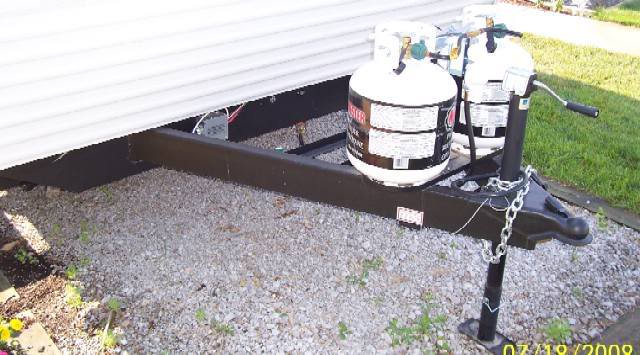

I happen to be at place where I could see this 2009 model, 6,000# GVWR rated TT. It was about 24 feet long and this frame caught my eye. See here. It looks like this header is used on 2 different size A frame and they weld a small angle piece over the larger A frame hole. This frame is made up of 6” I beam with a 5” tube tongue. The header is larger then the 6” I beam and has a larger lower flange then most I have seen. Also the A frame goes thru the header on top. And they attach the A frame to the I beam differently then any I have seen before. From the looks of our recent failures, this frame appears more substantial and on a 6,000# GVWR TT.

See here for your TT frame building curiosity.

I’m in the process of creating a better picture reply to show a progression of how I “think” the frames failed to add to the wording of my prior post. And also to talk about the last Sunline fix of Eman’s, KathyH’s and Good Ole Bob’s on why they did what they did to correct the problem. If anyone has any aspects on what bent first and why the new Sunline fix is successful, please post away your ideas. If we can understand “why” the first 2 design attempts failed and “why” the last design revision worked, this may present different options on how to fix the problem and or prevent it if yours has not yet become bent with the questionable design.

Like I stated earlier, many of the same combinations that Sunline used in the 2005 frame redesign exist on other brand TT’s. The question is, which are good or bad combinations.

Hope this helps

John

PS GoodOleBob, WOW great to hear from you again.  Hope all is well.

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

07-21-2008, 06:55 AM

07-21-2008, 06:55 AM

|

#123

|

|

Moderator

Join Date: Dec 2006

Location: Pennsylvania

Posts: 2,285

SUN #128

|

Tweety is going to Lippert today. Pictures when she gets back

__________________

Pam

Lance 1475 "Snoopy"

2012 GMC Sierra 3500HD 4x4 D/A

2012 Arctic Fox 30U, SUNLINES - 2006 2753 "Tweety", 2007 QUE "QUEtSE", 2364, 1660

|

|

|

07-21-2008, 01:08 PM

07-21-2008, 01:08 PM

|

#124

|

|

Moderator

Join Date: Dec 2006

Location: Pennsylvania

Posts: 2,285

SUN #128

|

I called Lippert this morning at 8:45 and talked to Jason, who said he had someone who could weld up the Tweety today. So at noon we drove over to Lippert. They seem like nice folks that are interested in helping. Our bill was $91. We didn't even have to unhook the truck. Mark brought his mobile welding truck out to the parking lot and welded a 1x2x11guage box beam across the bottom of the header from I beam to I beam. In previous fixes they have only gone from A frame to A frame, but we really wanted a little overkill, and they agreed that it wasn't going to hurt anything to go all the way to the main frame. Steve discussed putting an angle bracket across the top of the A frame but they convinced him it isn't necessary. He also discussed the missing triangular piece that they used to weld under where the A frame connects to the I beam in the back, and they said that all the manufacturers have gotten away from that, in that it's just not necessary. He also mentioned that it's much easier to do this as a preventative measure before they header is bent.

As usual, sorry about the lousy photography.

He tacked the box to the I beams, A frame, and header all the way across.

The bend you see is NOT a stress bend, but was there from the factory.

Side view of the box beam

Front view

Welded to I beam

Welded to A Frame

When all the welding was done, he spray painted it for us. If you can get your trailer there, they were efficient, pleasant, helpful, and I thought the price was right.

__________________

Pam

Lance 1475 "Snoopy"

2012 GMC Sierra 3500HD 4x4 D/A

2012 Arctic Fox 30U, SUNLINES - 2006 2753 "Tweety", 2007 QUE "QUEtSE", 2364, 1660

|

|

|

07-21-2008, 01:43 PM

07-21-2008, 01:43 PM

|

#125

|

|

Senior Member

Join Date: Aug 2007

Location: New York

Posts: 404

SUN #385

|

Pam,

Thanks very much for the follow up to the repair done at Lippert. The 11 gauge rectangular box welded reinforcement under the header looks to be a very strong and adequate repair. Really, equal to twice the metal under the frames than the last Sunline frame redesign which was apparently successful!

I particularly agree that the Main frame to Main frame is overkill, but so what? More steel= even better!

The only thing that is regrettable is that they didn't do it gratis, since they made the frame, but $91 is reasonable to have complete peace of mind. I'm too far away to bring my Sunline to Lippert, so I'll have to shop around locally.

__________________

Rick

2007 Ford F150 FX4 Supercab 4x4, 5.4 FFV engine, 3.73LS.

|

|

|

07-21-2008, 02:59 PM

07-21-2008, 02:59 PM

|

#126

|

|

Moderator Emeritus

Join Date: Aug 2006

Location: West Virginia

Posts: 2,289

SUN #17

|

Pam,

Thanks for the information. There is no way I will tow Sunny that distance for a fix with as bad as my frame looks and is, I'll be a nervous wreck just towing it the 6 or 7 miles that I need to go. I just hope I hear pretty soon to bring it over.

Kitty

__________________

Sunny #18 2003 F-344SR #8157

Sunny #19 1997 T-2653 #5485

1999 Ford F350XLT DRW Crew Cab, Long bed 7.3 PSD

2002 VW Jetta TDI.. AKA: Kitty's Kruiser

|

|

|

07-22-2008, 10:20 AM

07-22-2008, 10:20 AM

|

#127

|

|

Senior Member

Join Date: May 2008

Location: Ontario

Posts: 663

SUN #597

|

Re: One Frame Fix

Quote:

|

Originally Posted by henryj

The front end of the 2499 is strong enough to tow in a straight line. It is being stressed by flexing A-frame as the wd bars load and unload during various transitions especially in turns and in backing up. In other words, the tighter you turn it and the bigger the bump you're backing over--and this includes just about any driveway, the bigger the stress. Any dip steep enough to drag the skid bars is also creating twisting even if moving in a straight line.

For my slightly bent 2499 we are going to reinforce the A-frame on both sides of the header. The first is at least 3" channel, laid on its side with the legs pointing down welded across the A-frame and welded to the I- beam main frame. It is not necessary to weld to the header and could be just far enough back to give the welder room to work. Heavy angle iron could work here too, but in theory the channel is better.

The second reinforcement is a 4" channel welded vertically between the A-frame legs where the wd brackets are located. In my case, Equal-i-zer, I have just enough room between the battery supports and the L-brackets to place this channel. This channel should have the top and bottom flanges cut off to create a "tongue" that will give an optimal fit with the existing A-frame channel.

A good welder will know how to do all this and not overheat the metal. He said the open gaps where the A-frame passes through the header are probably deliberate to avoid over welding and over heating such a small area of the header and these should not be filled in.

Those with badly bent and drooping headers will likely need a frame shop before welding in these supports.

Henry

|

My brother, Dave, headed home to IL this morning, the kids and grandkids went to Niagara Falls and I have the day off with a bad cold so I will catch up with some computer stuff.

Dave looked at Pam and Steve's post before he left and had a number of comments especially for 2499 owners.

There are two kinds of steel failures: stress--2499--and fatigue--could hit the other 7000 lb. trailers later--so he thinks this preemptive "repair" is a prudent move for all these trailers. The 2499 has obviously been pushed over the edge by this design--we have no idea how close to the edge the others are. No one has so far reported a failure in the other 7000 lb. trailers or whether they got the new frame in late 07 or not.

Lippert's 1 X 2 tube is definitely strong enough for the job, but 3" or 4" channel on its side or even angle iron could be used too. A welder might have a preference for one or the other and that is ok. It is not necessary to weld to the header and, in fact, nothing is to be gained by this as the reinforcement in this area completely takes over from the header keeping the A-frame properly located. The reinforcement should definitely extend to the I-beams--don't accept anything less. Whether this reinforcement is enough to prevent problems for the lighter 7000 lb. trailers, time will tell, but it is not enough for a 2499.

This reinforcement that Lippert did on Pam and Steve's 2753 is absolutely essential to relieve the light header from its task of having to contain the flexing A-frame. But, it is Dave's opinion that this alone is not the fix for a 2499. The steel welded to the A-frame behind the header is too far down the legs of the A-frame from the wd brackets where the flex originates. Some flex will still pass through the header before it hits the tube or channel reinforcement setting them up again for a future failure. Dave is sticking by his original recommendation that a 4" channel welded into and across the 4" channel of the A-frame around the wd brackets is the fix we are looking for. He said this creates a very strong unified structure across the full height of the A-frame's channels that the wd bars will not be able to twist. Not only is this an elegant solution with a factory look to it, it is far stronger than any amount of steel welded across the top or bottom of the A-frame. It is definitely more time consuming and therefore more expensive than welding angle iron across the top of the A-frame.

In case your wondering, if this is so great, why not use it behind the header as well... The strongest reinforcement should be where the stress originates. Doing the same thing behind the header is massive overkill because the A-frame isn't going to be flexing anymore. Also, overhead welding is the trickiest to get quality welds and more welding and closer to the plastic Darco membrane and wood floor are hazardous.

Then, you might also be wondering, if this is so great why bother reinforcing behind the header at all... The header has already been compromised in all 2499s, including mine, and it needs the help of a tube or channel, both laid on their side, to make up what it's lost.

I've been too busy, and now sick, to look for a welder, but I hope to have this done in the next two weeks and will let you know how it goes.

Henry

__________________

2019 F150 3.5L Max Tow

2014 Arctic Fox 22G

2005 Sunline T-2499

|

|

|

07-22-2008, 06:18 PM

07-22-2008, 06:18 PM

|

#128

|

|

Senior Member

Join Date: Sep 2006

Location: Ontario

Posts: 503

SUN #43

|

I have been away from this forum for a while and then last week I met up with 2beagles at another forum Rally and he told me about this thread and suggested I check it out. All I can say at this time is WOW!! I am surprised at the frame failure issue. I am sorry to see how many of you have had to deal with this issue and can only image the frustration all of you have had to deal with. We can all be thankful we have this forum to share ideas and problems and help solve issues such as this one. I have read through this thread several times to make sure I fully understood what was happenning. I have a T2753 2005 Sunline. After reading the thread I went and checked out my frame and so far there is not sign of bending. For the record I am running the Equal-I-Zer hitch with the 1200 lb bars. I have towed my Sunline approximately 10,000 miles. I believe I am running a tongue weight of between 800 and 900 lbs depending on whether or not I am running with a full fresh water tank or not, but I will check this on a scale the next chance I get. I spoke to the our truck and trailer maintenance manager at work regarding the frame issue and showed him many of the photos. He agrees with henryj's brother on how to fix the frame.

henryj, it looks like you and I have purchased from the same out of business Sunline dealer (The Coachouse). I am curious if you now deal with Mobilife for all of your service work or not?

__________________

|

|

|

07-23-2008, 09:38 AM

07-23-2008, 09:38 AM

|

#129

|

|

Senior Member

Join Date: Aug 2007

Location: New York

Posts: 404

SUN #385

|

Henry,

Thanks for posting your brothers take on the repairs necessary to the T2499. I do tend to agree that the idea of strengthening the the A frame at the WD points seems a good one. I did, after all, suggest the angle iron across the a frame, early on. At this point, though, I wonder how necessary it really is.

The A frame on almost any trailer will likely twist a certain amount in normal use, I'm sure that is part of the design. Too much twisting can be bad, too little twisting can be bad. In reflecting on the cases posted here, I don't think that the issue is A frame flex, I think that it is lack of support of the A frame at the header. Note that when Sunline corrected the problem on the late 07 units it was through increased support (material) on the header below the A frame. They could have, instead, gone to a 5" A frame or reinforced the WD attachment area or a heavier duty header but they didn't. Also, Lippert recommended not to weld reinforcement forward on the A frame when they reinforced Tweety.

The fact that emans VERY heavily overloaded 2499 shows absolutely no problem (knock on wood) with the only difference being that this unit has the extra lower header support should speak volumes about this being the critical feature. Emans unit has tons of miles on it and has a very heavily loaded tongue with 4 batteries on top of the A frame. If any unit was going to twist the frame I would have to think that this would be it.

I would be very interested to see if the Engineering Department at Lippert has reviewed this situation and has a different "fix". I suspect that in the end, the header reinforcement is the critical issue in this case.

__________________

Rick

2007 Ford F150 FX4 Supercab 4x4, 5.4 FFV engine, 3.73LS.

|

|

|

07-23-2008, 12:26 PM

07-23-2008, 12:26 PM

|

#130

|

|

Moderator

Join Date: Dec 2006

Location: Pennsylvania

Posts: 2,285

SUN #128

|

Eman also has mountain bikes on a rack hanging on the front of his trailer. Lipperts "fix" is usually to weld the piece we have ONLY between the A frames. They siad they have done it that way for 5 years and not had anyone return with a problem. We went the little extra to the I beam, just for our own peace of mind.

__________________

Pam

Lance 1475 "Snoopy"

2012 GMC Sierra 3500HD 4x4 D/A

2012 Arctic Fox 30U, SUNLINES - 2006 2753 "Tweety", 2007 QUE "QUEtSE", 2364, 1660

|

|

|

07-23-2008, 01:46 PM

07-23-2008, 01:46 PM

|

#131

|

|

Senior Member

Join Date: Aug 2007

Location: New York

Posts: 404

SUN #385

|

Pam,

Thanks for that information. I think what you had done is what I'm also going to do. Just reinforcing the header/Aframe area appears to have done the trick in those other cases but I like the assurance of the additional tie in with the main frame.

I forgot, in my previous post to you, that you had this done as a precautionary measure. Actually, considering that it wasn't a warranty issue, that charge was VERY reasonable!

Wish I was close enough to them to have it done by them.

__________________

Rick

2007 Ford F150 FX4 Supercab 4x4, 5.4 FFV engine, 3.73LS.

|

|

|

07-23-2008, 07:24 PM

07-23-2008, 07:24 PM

|

#132

|

|

Senior Member

Join Date: May 2008

Location: Ontario

Posts: 663

SUN #597

|

Pam,

So Lippert has been doing this for 5 years! ...interesting...

Rick,

It's kind of a chicken and egg thing. Did the header break because it's too weak or because the A-frame flexed too much. You could make a case for either.

I didn't read the whole thread again, but I believe the latest frames had a 10 gauge header, a much wider lower flange and the A-frame passing through the middle of the header. All of these are significant in the frame that Pat has so kindly torture tested for us for 60,000 mi. Obviously retrofitting to this proven design is prohibitively expensive so the object is to get as close to it as we possibly can. IMHO a tube welded across the A-frame, as Lippert apparently has been doing, doesn't add up to 10 gauge, wide flange, A-frame in the middle. I don't believe we have yet seen failures of even all the 2499s in Sunline Club, although we have a couple of 2363s now too. And we have virtually no info on the progression of the failure. My 2499, even with 10,000 mi., seems to be the least damaged so the quick cheaper fix is tempting, but how close am I to the huge failures that most other owners didn't even see coming?

I wish we knew how much flex the A-frame has with the newer design. I still think the 4" A-frame is too light and that we have to reduce its flex. If you look at one of my original photos, or your own trailer, you'll see the A-frame is the same size as the coupler. It doesn't even look right on this size trailer. If you look through RV buying guides you won't see many if any trailers in the 2499's class that have a dry tongue weight as high and on top of that the 2499 loads everything in front of the axles.

Even car manufacturers have failures after years of testing so I suppose some of this is inevitable and I doubt very much that the RV industry has much excitement or challenge to offer any engineer. But I think it's pathetic that they can put such an untested inferior design onto the public road system. Oops... I'm on my soap box again.

Henry

__________________

2019 F150 3.5L Max Tow

2014 Arctic Fox 22G

2005 Sunline T-2499

|

|

|

07-24-2008, 01:21 AM

07-24-2008, 01:21 AM

|

#133

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,654

SUN #89

|

I know many of you have been thinking about this frame issue a lot, myself included.

We have been focusing on the header however I have not found any one yet check to see if the actual 4” channel is bent in the long direction. Or I missed it in this long post. This may only show up on the TT’s that have the larger header bends. It may not be there, but if it is, it needs to be part of the discussion.

I wish I was closer to one of you with the heavy header bends as I could assist in measuring this for you. If you have time to do this, this is one way to go about it.

I have taken a picture of my larger camper to show one way on how to do this.

To add to the mix I have also measured my T310SR (10,000# GVWR) frame which is 6” channel for any deformation of the 6” channel. There is none. This TT is loaded with a 1275# tongue at the present. It will go up once I’m done loading it to around 1,400#. I use 1,700# WD bars on this TT. See here on how I did this. I used a 4’ level and 2, 1/2" drive sockets the same length as spacers and lightly clamped in place. And then slide a scale up and down the length of the level to see if the number changed

I also did this same measuring on my 2004 T2499, (7,000# GVWR) a known 1,200# tongue using 1,200# WD bars for over 15K miles. This is 5” channel and a 10 gage header but still a small lower flange. There is no deformation on the channel to within 0.005” measuring. The paint thickness is at least that much so I declare that as none. And there is no twisting. See here. I used both the scale and a caliper on this one.

If some one with a heavily deformed header can try to measure if the 4” channel is bent along the length like I have shown, this can help if we are only fighting a twisting problem.

If some one with a heavily deformed header can try to measure if the 4” channel is bent along the length like I have shown, this can help if we are only fighting a twisting problem.

Here is where I am going with this. The fix at Lippert’s on Tweety’s rig seems simple and it is. Both that fix, Bink68’s fix and Henry’s brother suggestions all lead to the same conclusion that if you prevent the bottom of the channel iron at the header from twisting inward that will strengthen the A frame. I do agree this will do what it is intended to do which is, strengthen what is there now. I also agree that taking that support member all the way to the main frame rails adds more strength and costs not a lot more.

This still leaves us with a few unknowns yet unanswered. It may be we will never know, however we may have now hit critical mass on trying to find out. The problem is showing up on other models like the T2363. The way this 2005 A frame is made in the early versions seems to fail when a certain loading is exceeded. A real good question is, what it that load that makes this A frame fail? Good question and that would be good to know so a TT owner can try and not put too much weight in the back of the truck or on the tongue of the TT. And if they knew this with and without the propsed fixes.

What guide does one use? For proper towing safety, the WD on the TV must be set correctly. This should not be compromised in any event to try to save the A frame of a TT. The size of the WD bar needs to be such that is will properly match the tongue weight of the TT and any TV bed load aft of the rear axle. Most folks carry something in the TV behind the rear axle, this is normal. Then can however load differently once they know what not to do.

We have had 750# bars bend this frame as well at 1,200# bars. So changing a WD bar to fix this problem at least for the T2499 is not the solution.

The next piece is the frame itself. This is what started all this….

So what did Sunline miss when they went from the prior 2004 version to the 2005 redesign? I have not yet pulled all this together yet but here is part what I have found out.

We have now convinced ourselves that when a certain loading occurs the 2005 4” channel, 6” wide, 12 gage, small lower flange header design it will twist at the C channel and bow the header. The basic header went from 10 gage (0.1345”) thick in 2004 down to 12 gage (0.1046”) in 2005. Basically 0.0299” difference or for all practical purposes 1/32”. I have found many other TT builders use 6” wide 12 gage headers as I posted the pic’s of those that also have a very small lower flange. So why are there’s not failing?

Here are a few facts I dug up on the channel and the way the 2004 and 2005 frames are built. Both headers are “close” in design, the 1/32” thickness while the 2004 is stronger, I do not think it is what broke the camels back all in itself.

Next is the channel itself. They make several thickness channels and what is normally used is the lightest per foot weight for this application by Sunline or most anyone else. The web thickness being the change. Actually going to the heavier web is not as common a channel iron but is in the text books and is stronger per the same outside overall height.

Here are a few things I dug up. Source: Steel Construction Manual 7th edition. Page 1-50. For the same loading on a piece of channel iron using the lightest grade, the stress per 4, 5 and 6” channel iron are as follows in bending:

Using 6” channel as the strongest in this comparision and the same loading (tongue wt and TV weight) on all 3 channels:

6” channel will have 45% less stress in it then 5” channel.

5” channel will have 56% less stress in it then 4” channel.

6” channel will have 126% less stress in it then 4” channel.

All 3 channels have the same yield stress level as that are all made out of the same steel. When you approach the yield point, permanent deformation will occur and the metal will start to bent. If the stress keeps building the bending will continue until the stress values hit the tensile or ultimate stress and then the part will break.

The T2499 floor plan has not changed with the 2005 frame redesign. 1,000 and 1,200# tongue weights can still occur. The move from 5” channel to 4” channel did change the safety factor. Each time I redo this, the 5” channel can carry 56% more weight then the 4” channel before reaching the yield point.

So I went into other brands tubular A frames verses the channel iron. Well the tube shape changes the moment of inertia (I value) of that shape. Putting this into simpler terms, the larger the moment of inertia (I) of a shape the stronger it is in this application.

For reference

C4 channel at 0.184” web thickness has a I = 3.85 in. (4)th

C5 channel at 0.190” web thickness has a I = 7.49 in. (4)th

C6 channel at 0.200” web thickness has a I = 13.1 in. (4)th

Using a 2 x 4 tube A frame with 0.115” wall has a I = 2.76 in. (4)th

Using a 2 x 5 tube A frame with 0.115” wall has a I = 4.83 in. (4)th

Using a 2.25 x 5 tube A frame with 0.115” wall has a I = 5.188 in. (4)th

Using a 2.25 x 6 tube A frame with 0.115” wall has a I = 8.667 in. (4)th

So what does all this mean? Well the 5” channel in pure bending is stronger then many tube frames until you go to 6” or until you change the wall thickness or width of the tube. The 0.115” wall thickness I found was common in other brands so I used it for comparison.

The next area is the ability to resist twisting. I have to do more digging on this one and report back. The ability to resist twisting may be of higher importance then the actual load carrying. What I’m trying to back into is the prior 5” channel I know yields more load carrying ability, it may also have given enough resistance to twisting that it compensated for the header design in the 2004 vintage which does not differ a whole lot from the 2005 vintage header.

Or in simpler terms, did the 5” channel keep the header from buckling where now the fixes proposed to date are addressing the 4” channel to not twist which then buckles the header??

If some one with a bent up header can check the 4” channel for being bent in the horizontal direction, we can maybe put that part to rest.

Eman can you check yours as well?

And thinking on this more, Eman’s added battery frame I feel added a level of A frame twisting resistance to his A frame. The top of the channel iron cannot twist in that area as it is rigidly tied to the other side. The bottom can still flex, but it will take more load to cause a permanent twist. This coupled with the fact that his A frame penetrated the center of the header along with the load distributing plate welded next to it coupled with a larger lower flange. Basically if the A frame does twist, it does not have the exact same effect of buckling the bottom of the header as the flex is occurring in the center of the header as opposed to the bottom of it where the header can break apart.

My looking into this deeper is not to change any ones mind on a direction of a fix, but more to understand the actual root cause. This may help explain why the new latest 2007 frames seem to be OK and if we can figure out how to prevent it from occurring on other models with this new frame style.

Hope this helps

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

07-24-2008, 07:28 AM

07-24-2008, 07:28 AM

|

#134

|

|

Senior Member

Join Date: Aug 2007

Location: New York

Posts: 404

SUN #385

|

Henry,

Yes, I noticed the 5 years of repair comment too. Someone, earlier, mentioned that there were a number of frame failures coming up in a search for Lippert Components. Possibly the 5 years refers to other brands of TT, with frames made by Lippert, that have had problems.

I totally agree about your concern about the A frame size and it really is a chicken or egg scenario with this problem. I think both changes play a part in the failures. I will say that I looked back in this thread and did not see where the later frames were changed to a 10 gauge header. I see where the A frame goes through the header at a higher point and the small plate was welded on the side. Possibly I missed that.

I would think that an 11 gauge tube attached along the header and both frames would be substantially stronger than the later frame redesign. Now you have almost twice the strength (steel) and rigidity below the main and A frame. I don't see how it would stop the A frame flex further up the A frame but it will certainly stop the header collapse, which is the problem at hand.

I don't know how much of a problem that the 4" A frame flex will be down the road, emans Sunline has certainly torture tested the A frame completely with seemingly no ill effects. JohnB does point out, and rightly so, that the battery frames are located on top of the A frame and do stabilize it there. One thing that I would like to know is whether the big battery frame on emans unit is bolted or welded to the A frame. I would also like to know, for sure, if these later units have a 10 or 12 gauge header.

JohnB,

I'll try to get the data you suggested. Thanks for the clever examples of the tools needed to get those figures!

__________________

Rick

2007 Ford F150 FX4 Supercab 4x4, 5.4 FFV engine, 3.73LS.

|

|

|

07-24-2008, 08:09 AM

07-24-2008, 08:09 AM

|

#135

|

|

Moderator Emeritus

Join Date: Aug 2006

Location: West Virginia

Posts: 2,289

SUN #17

|

WOW John,

Thanks for all your technical information. I'm not sure I'll know how to set up checking the A-frame on Sunny, but I'll try, hopefully today.

As to how my truck is loaded, well normally all that is loaded to the rear of my axles are the 3 X-pens for KD, The Weber Q 100 and 15 gallons of diesel(only when I head out west). On my truck that stuff really is NO load at all.

I have another concern about a fix. Even thought I have NO plans to sell Sunny, I happen to think about "WHAT" people (dealer or prospective new buyer) will think when they see the added welded on metal.

I am hoping my sons trailer builder friend (Ryan) comes over "REAL" soon to see the mess. (my son is on midnights, but he e-mailed me to tell me he received a call from Ryan, but he was sleeping so he's going to return the call when he wakes up later this morning.

__________________

Sunny #18 2003 F-344SR #8157

Sunny #19 1997 T-2653 #5485

1999 Ford F350XLT DRW Crew Cab, Long bed 7.3 PSD

2002 VW Jetta TDI.. AKA: Kitty's Kruiser

|

|

|

07-24-2008, 08:15 AM

07-24-2008, 08:15 AM

|

#136

|

|

Moderator

Join Date: Dec 2006

Location: Pennsylvania

Posts: 2,285

SUN #128

|

To address some of ya'lls questions.

1. I had the IMPRESSION that frame problems included other brands, and different issues. They made / make frames for lots of manufacturers around here that made and still do make trailers. They also do repairs, and have some funny stories of what owners do that cause issues. (not that they were implying the Sunline problems are self inflicted)

2. The guy at Lippert says the header is the problem, hence their ability to convince us that we didn't need the piece across the top of the Aframe. (which we originally requested) Also, we originally thought the welds would just be at the Aframe and IBeam, but it is THEIR practice to also weld across the header.

3. 2007 Sunlines have a 10 guage header

4. Kitty, our fix is really not evident when you just look at the trailer. You have to crawl under it to notice it.

Pam

__________________

Pam

Lance 1475 "Snoopy"

2012 GMC Sierra 3500HD 4x4 D/A

2012 Arctic Fox 30U, SUNLINES - 2006 2753 "Tweety", 2007 QUE "QUEtSE", 2364, 1660

|

|

|

07-24-2008, 11:07 AM

07-24-2008, 11:07 AM

|

#137

|

|

Moderator Emeritus

Join Date: Aug 2006

Location: West Virginia

Posts: 2,289

SUN #17

|

__________________

Sunny #18 2003 F-344SR #8157

Sunny #19 1997 T-2653 #5485

1999 Ford F350XLT DRW Crew Cab, Long bed 7.3 PSD

2002 VW Jetta TDI.. AKA: Kitty's Kruiser

|

|

|

07-24-2008, 08:13 PM

07-24-2008, 08:13 PM

|

#138

|

|

Moderator Emeritus

Join Date: Aug 2006

Location: West Virginia

Posts: 2,289

SUN #17

|

OK, Sunny has been looked at, trailer builder was furious. He said he'd never buy a trailer from Sunline. I explained all about Sunline to him, and that Lippert Frames actually built the frames, supposedly to Sunline specs. Well, anyway, Sunny is going to get his frame fixed, welded, reinforced made strong "So I'll never have to worry about it again". Also I will be getting a 3inch lift. Do you think that will be too much, should I just go for 2 inches ? And he will be removing the skid bars and installing wheels for me. Said probably want Sunny in about 2 or 2.5 weeks, maybe sooner.

He also said, that he really wouldn't tow these things far until the frames were beefed up to support the weight.

He was shocked at how flimsy the tongue/header and battery tray were, so that will all be taken care of. Estimate right now is about 700 bux for everything.

That will leave me a little $$ so I can hopefuly still go away for Labor day weekend.

He is also going to look at our site and see the carnage & posts.

Kitty

PS: Le me know which height lift you think would be best.

Kitty

__________________

Sunny #18 2003 F-344SR #8157

Sunny #19 1997 T-2653 #5485

1999 Ford F350XLT DRW Crew Cab, Long bed 7.3 PSD

2002 VW Jetta TDI.. AKA: Kitty's Kruiser

|

|

|

07-24-2008, 08:26 PM

07-24-2008, 08:26 PM

|

#139

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,654

SUN #89

|

Kitty

Your amazing….  WOW.

However I cannot tell from your setup if the 4" channel is bent or not the way you measured.

Try this. See the pic. Move the 1 socket all the way to the end under the camper. The level is now a straight line between the 2 furthest points.

Then, do 1 of 2 things.

1. Find a 3rd socket the exact same height, line up all 3 next to each other and put a straight edge across the top to check and look for daylight or a gap. Then you know you have 3 of the same length. Then mount as shown and use the 3rd socket as what we call a “feeler” gage. Meaning sliding the gage the full length area. If the header is bent up, you can tell you cannot force it in as the socket would be to big. Hold the level up firmly but not to hard to deflect something while doing the “feeling” so the 2 end sockets are dead tight to the frame and so is the level up against them.

2. Still do your tape measure however slide it along the full length looking for the gap to get smaller/larger near the header. I cannot read the gradations off your pic. To fuzzy. The camera was focusing on the grass in the background. It looked like you had mm or 1/32” gradations on the one side of the tape. Count those little lines as you have the tape end pushed all the way up to take out the end tab play of the tape.

Unfortunately I forgot to tell you to not measure so close to the ends where the socket are for actual deflection as really all you are measuring there is the socket height. And to space the 2 sockets out across the entire length. It is more accurate that way. Yes I know have to crawl under, sorry.

Ideally if Bink68 or Clarkldc has time to measure theirs as they have it the worst it will be a good field test.

Ideally if Bink68 or Clarkldc has time to measure theirs as they have it the worst it will be a good field test.

Thanks

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

07-24-2008, 09:49 PM

07-24-2008, 09:49 PM

|

#140

|

|

Moderator Emeritus

Join Date: Aug 2006

Location: West Virginia

Posts: 2,289

SUN #17

|

OK John,

I'll try to get that info tomorrow, and I'll put camera on super-macro to see if it works better. The level and sockets are still in place. In my measuring, I had exactly 1.5 inches in the spots that I checked.

Hopefully, I'll post some more results tomorrow.

And then once Sunny is fixed and lifted ( 2 or 3 inch? ) I'll need to re-set the hitch, and I've never done that, Stoltzfus set it up for me.

Lots of leaning going on here for me.

Thanks for all the help,

Kitty

__________________

__________________

Sunny #18 2003 F-344SR #8157

Sunny #19 1997 T-2653 #5485

1999 Ford F350XLT DRW Crew Cab, Long bed 7.3 PSD

2002 VW Jetta TDI.. AKA: Kitty's Kruiser

|

|

|

|

|

|

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Sunline Discussions

» Recent Sunline Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rick

Rick

Linear Mode

Linear Mode