|

|

09-10-2014, 05:57 PM

09-10-2014, 05:57 PM

|

#1

|

|

Junior Member

Join Date: Aug 2014

Location: Maryland

Posts: 20

SUN #6660

|

264SR slide out not level

I just bought a 2004 264SR. I need a little help. I have done a lot of research on here before posting (I didn't want to start a new thread if this subject had already been covered.) I think I have 2 basic problems: when extending the slide out, the gear on the driven(right side if you are standing inside) will skip teeth, causing it to go out of square. I can't figure out what is making it skip. Anyway, after squaring things up again, and fully extending it, the right side is 1 3/4" lower than the left. When I retract the room, the right side is only 1" lower than the left.

The adjustment underneath on the right slide rail is already jacked about 1 inch higher than the left, so I am clueless as to what to do.

A couple of things to note: The right wall has been repaired before, and will need to be repaired again (poor repair the first time.) The floor systems to be very solid, so I don't think bad wood is an issue.

Any ideas or suggestions would be greatly appreciated!

__________________

__________________

|

|

|

09-11-2014, 09:53 PM

09-11-2014, 09:53 PM

|

#2

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Hi Ljackson,

I may be able to help.

Can you take a pic or too of the gear teeth you are seeing skip teeth? Your 2004 unit has the Lippert rack and pinnion system.

There is a master rack, (the one the motor drive is on)

And a slave rack, (the one driven by the square shaft off the master rack)

I'm assuming you area saying you are jumping gear teeth on the rack gear on the bottom of the slide arms? Or are you jumping teeth inside the gear motor?

Since you said, jumping teeth and going out of square, that points to the rack and pinnion gear drive with the square shaft. If you are actually jumping teeth, this points to the bearing setup of the little idler shaft being loose or shot allowing the teeth of the pinnion gear to come jumped from the long rack gear. Or some other condition allowing the gears to come unmeshed.

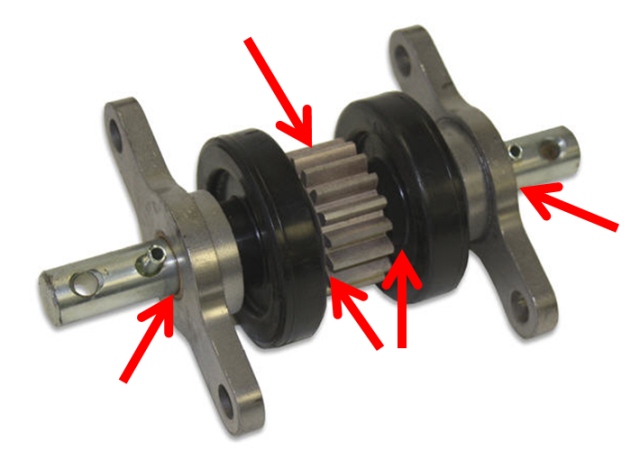

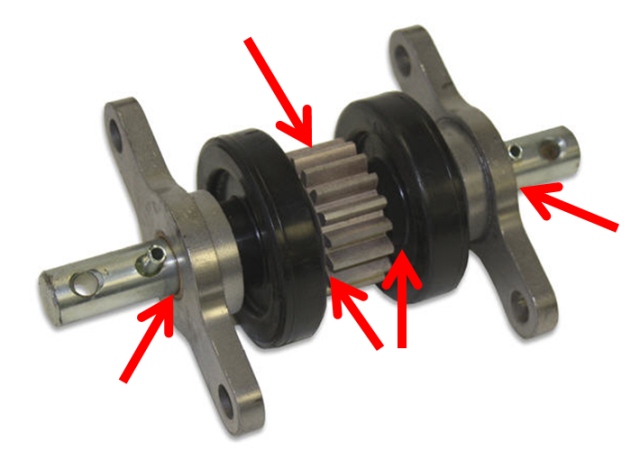

Here is a pic of the slave rack and the pinnion gear and bearings I am talking about. There is a similar setup on the master rack.

If this is the area you are seeing teeth actually jump, then that pinnion gear is not meshing correctly into the rack gear. The bearings or pinnion axle bushing may be shot, the end caps loose or out of position.

OR Check here. There are wear pads on the slide arms. If the top 2 wear pads are missing or shot, it can let the slide arm raise up and un-engage the gear teeth

See the 2 pads on top and then a pad on the left and right

The little pads looks like this

Those pads "normally" do not get a lot of wear unless something is not setup right. And the tops ones should not get a lot of wear as the arm really does not normally hop up. But you said something was working on this, so something to check.

There is also a roller inside the slide arm. Way up on the inside end. This roller supports the arm weight up. If that roller or the bearing in that roller is shot, the arm may be lifting and then jumping teeth. Check and see if there is a lot of play in this roller.

Hope this helps. I'm going to be off line until Monday night but try and look at these areas and post some pic's. Can see more what you are up against.

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

09-15-2014, 11:17 AM

09-15-2014, 11:17 AM

|

#3

|

|

Junior Member

Join Date: Aug 2014

Location: Maryland

Posts: 20

SUN #6660

|

Hi John,

Thanks so much for the advice, you are quite an asset to this forum! I will try to get some pics tonight. The trouble is, my work is getting in the way of my quickly growing Sunline habit! I think those pads are missing. I will look again tonight, and provide more details. Thanks again!

__________________

|

|

|

09-15-2014, 06:23 PM

09-15-2014, 06:23 PM

|

#4

|

|

Senior Member

Join Date: Jan 2009

Location: Rhode Island

Posts: 1,515

SUN #768

|

Quote:

Originally Posted by ljackson

hi john,

thanks so much for the advice, you are quite an asset to this forum! ...

|

Amen!

__________________

Gene & DW Ginny

Gene & DW Ginny

2002 Sunline T-2363

2008 Toyota 4-runner 4wd 4.7L V-8

Reese Dual Cam straightline - P3 Brake controller

|

|

|

09-15-2014, 06:51 PM

09-15-2014, 06:51 PM

|

#5

|

|

Junior Member

Join Date: Aug 2014

Location: Maryland

Posts: 20

SUN #6660

|

Here are some pictures I took this evening. It would only allow me to upload 3 at a time. The first 2 are of the driven side slide. The 3rd is of the wall? adjustment

__________________

|

|

|

09-16-2014, 08:12 PM

09-16-2014, 08:12 PM

|

#6

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Hi Again,

I made it back from camping.

Yours is the Lippert Rack and Pinion system. Same as mine and many others here on the forum.

So if you are jumping gear rack teeth, yes what I typed fits on that to go looking for.

And HEADS UP

This pic shows what looks like a cracked spring hanger just barely hanging on for dear life.... The spring hanger is connected to the leaf spring. If that is cracked, need to get it fixed before you head out very far.

If you still cannot find the reason for the jumping, post some pics of the areas I talked about inspecting. There are only so many places that can cause it to jump teeth.

Hope this helps and good luck

John

PS, thanks for the good words. Glad to help as I can.

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

09-17-2014, 08:19 PM

09-17-2014, 08:19 PM

|

#7

|

|

Junior Member

Join Date: Aug 2014

Location: Maryland

Posts: 20

SUN #6660

|

I'll try to get another look tomorrow. Thanks again John!

__________________

|

|

|

09-18-2014, 06:22 PM

09-18-2014, 06:22 PM

|

#8

|

|

Junior Member

Join Date: Aug 2014

Location: Maryland

Posts: 20

SUN #6660

|

Hi John,

I was able to do more investigating, and learned a lot. It is actually the master side that is jumping teeth. On the slave side, the rack gear doesn't touch the bottom of the track that it rides in. On the master side, it does drag the bottom. During the first 6 inches of opening, the gear jumps twice. You can see the rack push upward when the teeth jump. After that, it opens smoothly the rest of the way.

Do you have any thoughts on why the master side is dragging the bottom of the track? I can't tell the condition of the roller at the other end the rack.

Thanks again for your help!

__________________

|

|

|

09-18-2014, 09:02 PM

09-18-2014, 09:02 PM

|

#9

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

This is good info.

The power to move the slide room the 1st 6" of opening can take a lot of power. The seals are breaking loose from the side of the camper and that takes a lot of power. This increased power puts pressure on the gear drive and forces the gears apart if there is excess play between the teeth. Mechanically somehow there is excess play to allow the teeth to come diss-engaged. Either the slide arm can pop up or the square shaft pinion drop down.(loose hardware, worn bearing, worn bushings)

Try and take some good pics of the part you see jumping up and post. I may be able to see something.

Are the plastic wear pads still good and thick on the top. You can see 2 of them here. If they are worn thin, the inner rack arm can rise up. The pinnion gear running the sq shaft is attached to the outer rack arm/tube that does not move. There is excess play between the 2 areas.

NOTE: the pic above is the slave rack.

This pics shows the master rack with only 1 wear pad on top. But this is not my slide in the pic. I do not have a pic of the top of the slide arm. I can get one if needed.

Here is the side view of the master rack showing the pinnion plates attached to the outer slide arm frame

Check the bolts and if there are large holes that the pinnion assembly may have dropped down creating less teeth engagement

Now to your comment the master rack drags the bottom. Do you see grinding wear marks on the bottom sides of the master rack arm? It would leave tracks/marks if it was.

The master arm bottom surface is suppose to be riding on the bearing outside diameter of the pinnion . In this pic the black bearings are suppose to be supporting the bottom of the master rack slide arm that extends out. If the bearings are shot, the arm will drop and possibly drag on the outer fixed slide arm tube. Also if the pinnion shaft bronze bushing area shot, the pinnion shaft can drop down.

See here on my slave rack

You should see rolling witness lines on the bottom of the slide arm, but there should not be grinding going on.

If you lube the slide seals with spray on silicone OR 303 UV protectant or slide gasket lube it will help lower the first 6" break away power.

Hope this helps

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

09-18-2014, 09:06 PM

09-18-2014, 09:06 PM

|

#10

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

This may help too 2 x 2 Electric Slide System

There are parts there and below a manual on the slide mechanism from Lippert. The manual does not tell all the Sunline methods of the slide, but it does help on the actual slide mechanism.

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

09-18-2014, 09:07 PM

09-18-2014, 09:07 PM

|

#11

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

PS, what did you find out on the spring hanger? Was it cracked or a picture anomaly?

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

09-19-2014, 06:08 PM

09-19-2014, 06:08 PM

|

#12

|

|

Junior Member

Join Date: Aug 2014

Location: Maryland

Posts: 20

SUN #6660

|

Hi John,

Thankfully, the spring hanger turned out to be a picture anomaly.

My arm only has the one pad on top. The pads don't appear to be worn out.. On Sunday I will get take the pinion gear off and inspect it and get some pics. Work is getting in the way of progress yet again!

__________________

|

|

|

09-19-2014, 07:44 PM

09-19-2014, 07:44 PM

|

#13

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Quote:

Originally Posted by ljackson

Hi John,

Thankfully, the spring hanger turned out to be a picture anomaly.

My arm only has the one pad on top. The pads don't appear to be worn out.. On Sunday I will get take the pinion gear off and inspect it and get some pics. Work is getting in the way of progress yet again!

|

Good news on the spring hanger!!!

Good luck on the pinnion gear. That area should turn up something or at least eliminate some things.

Work getting in the way of our camper habits...ah yeh, I can relate...

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

09-21-2014, 02:06 PM

09-21-2014, 02:06 PM

|

#14

|

|

Junior Member

Join Date: Aug 2014

Location: Maryland

Posts: 20

SUN #6660

|

Hi John,

I was able to to fix the jumping teeth problem. The dealership I bought the camper from couldn't get the slide to go in. I guess there was an issue with pinion gear on the master side, so they replaced the gear, rollers, and shaft that they roll on. Apparently, they couldn't get the bolt holes to line up, so instead of figuring out why, they drilled holes lower than the original, and in doing to made it so the rack gear was riding on the bottom of the tube instead of the rollers. I got a whole pinion gear assembly from a friend and got everything back together in the original holes. See the pics below.

__________________

|

|

|

09-21-2014, 02:29 PM

09-21-2014, 02:29 PM

|

#15

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Well that for sure will make the teeth jump....

Good for you sorting this out and getting it fixed right!

If you need any help or pointers on how to adjust the system, ask away. The adjustments, depending which ones are out are not exactly intuitive on which adjustment does which movement.

Odds are high it might not be right after this saga. I have seen on another members system just like this one where the prior owner did not have the stroke set right and they broke the wall supports over time pushing on it. I actually saw the wall jump a 1/4 to 1/2" when the slide went out full stroke. They had the out stop in the wrong place and over time it took it's toll on the wall supports.

Happy camping in your new coach!

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

09-21-2014, 02:47 PM

09-21-2014, 02:47 PM

|

#16

|

|

Junior Member

Join Date: Aug 2014

Location: Maryland

Posts: 20

SUN #6660

|

Now onto than the next issue. When the slideout is extended, the right is dropped dramatically lower than the left. Any ideas on this? The right side adjustment that is on the end of the rack gear is already higher then the left, so I am pretty clueless on what to do. Please see the pics below. Thanks!

__________________

|

|

|

09-21-2014, 03:23 PM

09-21-2014, 03:23 PM

|

#17

|

|

Junior Member

Join Date: Aug 2014

Location: Maryland

Posts: 20

SUN #6660

|

Sorry John,

I posted the second post before I realized you had commented. Thanks so much for your help! I sincerely appreciate you taking the time to offer tips and advice.

__________________

|

|

|

09-21-2014, 05:59 PM

09-21-2014, 05:59 PM

|

#18

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

I figured there would be more to the story...

This would be easier to tell you if the slide was OK for a long time, then not OK but this does not seem to be the case. At this point I cannot tell from what little we or you know how good or bad the actual slide room itself is. You state this:

Quote:

Originally Posted by ljackson

Anyway, after squaring things up again, and fully extending it, the right side is 1 3/4" lower than the left. When I retract the room, the right side is only 1" lower than the left.

The adjustment underneath on the right slide rail is already jacked about 1 inch higher than the left, so I am clueless as to what to do.

A couple of things to note: The right wall has been repaired before, and will need to be repaired again (poor repair the first time.) The floor systems to be very solid, so I don't think bad wood is an issue.

|

We need to better understand what is correct and then what is not correct so we know how to fix the right area. This is going to be a little trouble shooting mission to sort this out. Someone before you was adjusting the vertical adjustment at the ends of the slide arm trying to fix some problem. We have to back into what the issue is.

We need to check these things and then go from there.

1. Is either slide arm bent? The part the gear rack is welded too. Use a 4 foot level or other straight edge and check front and rear rack. You can put the straight edge right on the gear teeth even of the rack.

2. Is the slide floor tongue warped? The Sunline slide floor of your vintage has a tongue on it that extends beyond the inside flange face of the slide. If this is warped/cracked it can cause one end of the slide to be lower when the slide is out.

There was 2 slide floors in the 2004 model year, if yours was the last ones in the 2004 model year, it went to the plastic coated slide floor, plastic trough and rollers. And that is a different set of questions.

What month/year is the build date? Look on the VIN plate on the front left of the camper and it will tell you what month/year your 2004 model was built. At the very end of the 2004 year they changed the slide floor. By the one pic I have of your slide floor, I'm guessing it is built approx in April or before April 2004 or late 2003 and has the metal trough, Darco membrane floor. Need to confrim yours has a plastic mesh membrane on the bottom of the slide floor and a metal trough.

Here are some pics of mine and what yours should look like if yours was an early 2004 build. This is the plastic mesh membrane and the slide trough.

If you lift the rug flap up when the slide is out, you will see a galvanized metal trough on the floor under the slide. On the slide floor, a metal plate about 1/8" thick is on top of a 1" thick slide floor hanging off the slide tongue. The carpet pad is glued to the metal plate. Here are some in and then slide out pics

See here with the slide in

Also look when the slide is "in", measure from the end of the metal plate to the floor on the front and back of the slide. Mine was easy I has floor tile to more to, but compressed carpet can work too. Just try both ends the same. What are those numbers? Trying to find out when the slide is "in" how parallel the entire slide floor is the camper floor

Now extend the slide out. Lift the carpet flap. You will see the metal trough and the slide sitting down in the trough. Or is suppose to be sitting in the trough to create a flush floor.

If you look at the gap between the end of the slide floor to the metal trough along the full length of the slide, the floor and the trough should be fairly parallel front to back. Not on an angle. Note this.

Now to the warped tongue. I'm assuming you have a dinette and a jack knife couch. I'm going to tell you what you need to get, you will have to figure out with what you have to work with to check it.

If the slide floor tongue which extends beyond the wall is warped, we need to know this before trying to adjust anything. Need to use a 4 foot level or other straight edge and see if the tongue is warped in relation to the main slide floor in the slide itself. This is best to do at the walls if you can. But out in the middle will tell us something too. Here is with the rug up and pad. It is easy to do here but you do not have to tear the camper apart to get this, just showing a pic of mine. Even on the carpet you can see this too of the tongue is warped up.

Here is what a warped tongue on a slide floor looks like. See the end of the slide beyond the wall is warped up? This is on a Sunline 5er but can happen to a TT too given the right conditions. If yours is warped, it generally is warped the worst when the slide is out and drops the whole slide down. But when the slide is in, it still has a level of warp so you can check both in and out

I'll type more in the next reply on the outside of the camper.

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

09-21-2014, 06:33 PM

09-21-2014, 06:33 PM

|

#19

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

I forgot one thing, level the camper left to right and front to back as best you can when doing all these checks.

Before we go outside, 1 last thing to check inside. We already know that when your slide is out, the slide top flange is not parallel to the camper frame. Your pics show this. But we need to know about how the slide is clamping to the seals when the slide is out to see if the slide are out of location with the slide arm extension.

Extend the slide out. Tell me if you hear the click, click click of the slide drive overload clutch when you reach full out.

Now go and look at the ends of the slide. Look at the top and the bottom. You are looking to see if top and bottom of the slide is parallel to the wall. Is it? Look at the front seal area and the back seal area.

Here is the bottom. This pic shows the bottom is way out. Again yours may not be this far out (only pic I had to show) but measure the wall to the flange molding top and bottom for being parallel.

The top touching

OK now retract the slide and go outside. Get a step ladder and look how the slide fits in the slide flange of the camper.

You are looking at the gap between the slide room flange and the camper flange. That gap tells a story.

Look at the back corners

And the front corners

Is the gap along the slide top (horizontal) parallel between slide flange and camper flange?

Is the gap along the slide front (front vertical) top to bottom parallel between the slide flange and the camper flange?

Is the gap along the slide rear (rear vertical) top to bottom parallel between the slide flange and the camper flange?

Measure the gaps and report back. NOTE: The slide might be parallel vertically but shifted to the front or back. Aka, not in the middle of the camper flange hole, note this too. There is a adjustment for this too if needed.

Also lets convert the wording to slide front or slide rear. I do not know on your unit which you are referring to as right or left. If inside looking out is one thing and outside looking is another. Front and rear does not matter which way your looking.

Once we figure out how the slide is fitting in the camper hole, we can better then start to sort out where to go next.

I'll type one more check in next reply. The rack timing.

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

09-21-2014, 07:06 PM

09-21-2014, 07:06 PM

|

#20

|

|

Moderator

Join Date: Nov 2006

Location: Ohio

Posts: 12,649

SUN #89

|

Now to the slide arm rack timing and checking if the master rack is set correct and then the slave rack.

The master rack (the one with the motor drive) has stops for both full in and full out. We check that this is correct first, then the slave rack follows it.

Slide out stop. When the slide extends out, the acme screw system of the master rack is suppose to run out of mechanical stroke and you will stop by hearing the motor clutch ratchet. (like a portable clutch drill ratchet).

When jogging the slide out, the master rack inside seals are suppose touch, compress and once just fully compressed, you reach the end of stroke of the slide actuator and the clutch ratchets. The slide wall is not suppose to be the hard stop, running out of stroke on the actuator is.

When the slide is full out the master rack actuator will stop when it runs out of stroke. So the slide is adjusted in or out from this stop location to create the right slide seal squeeze/clamp.

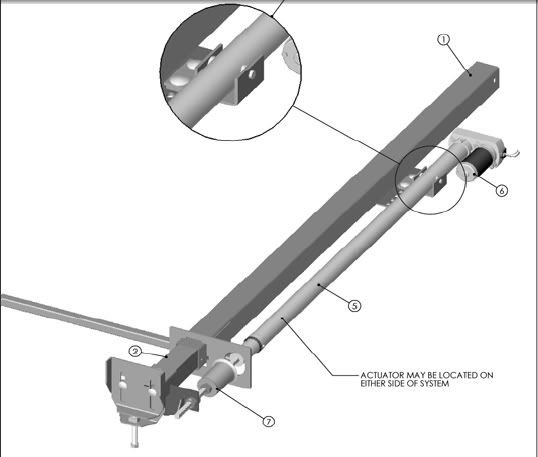

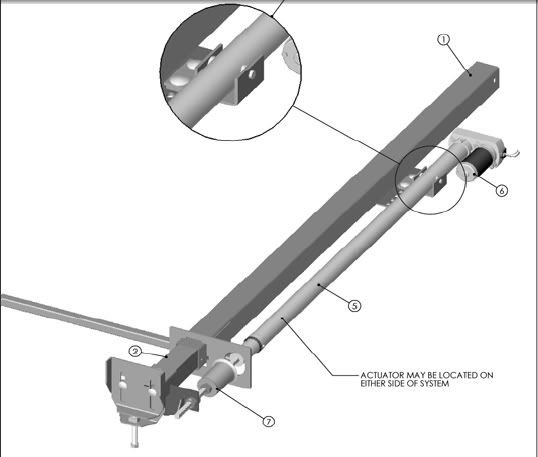

Slide full out

Slide master rack mechanism

Slide stop system for "Out"

The all thread rod that screws into the master rack actuator that is then held in location by "Jam nut 2" and "nylock nut" and this l holds the metal tab that pulls the master rack in and out. Moving this location of the nuts changes the Out position.

I do not know where yours is adjusted right now. If your not hearing the clutch trip on the way out, it just stalls out the motor, odds are high you are not reaching the end of stroke and you are over powering the wall as the stop. We will need to fix this after we get all the data.

The slave rack is then timed off the master rack for Out once the master is set correct for the Out direction. With the slide out, the square shaft is unbolted at the master rack end and the sq shaft adjusted (use a wrench on the sq shaft) to create the right squeeze on the slave end seals for the out direction. You can only adjust the square shaft 1/4 of a turn on the sq shaft. To get finer then 1/4 turn, the slave arm is slotted. This is out at the end of the slave arm. Sliding the slide arm in this slot will get between 1/4 of a turn.

Again, we are only looking to see how the seal are tight right now with the slide out.

When the slide comes in, the slide is built to create a parallel clamp the length the entire slide travel so when out is set, and no large gear back lash, slide clamp "in" will bottom out on the camper seals and a stop can agasint the camper frame at the exact same time and the slide seals fully compressed. The motor will stall out and not go any more. It "might" ratchet. Your vintage (Venture drive system) may not ratchet on the way in, only the way out. Other model years work a little different.

When the slide is in, the slide seal should be compressed even along the top and front and rear. Note what you have.

Right now we are not doing a lot of adjustment, just checking what you have. I explained the rack timing so it would make more sense to you as your looking. If and when we start adjusting for the slide room out and in adjustment, then timing may need a tweak and I'll go into this in more depth

Good luck. A lot to look at I know, but you have to understand the root cause of the issue before trying to adjust out of it.

Hope this helps

John

__________________

Current Sunlines: 2004 T310SR, 2004 T1950, 2004 T2475, 2007 T2499, 2004 T317SR

Prior Sunlines: 2004 T2499 - Fern Blue

2005 Ford F350 Lariat, 6.8L V10 W/ 4.10 rear axle, CC, Short Bed, SRW. Reese HP trunnion bar hitch W/ HP DC

Google Custom Search For Sunline Owners Club

Google Custom Search For Sunline Owners Club

|

|

|

|

|

|

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)

|

|

|

| Thread Tools |

Search this Thread |

|

|

|

| Display Modes |

Linear Mode Linear Mode

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Sunline Discussions

» Recent Sunline Discussions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Linear Mode

Linear Mode